Synthetic chemistry saw serious leaps in the mid-20th century, and silane chemistry made its mark as part of a broader effort to improve adhesion and surface modification. As industries demanded better coupling agents for organic and inorganic interface challenges, chemists focused on aminosilanes. Out of this drive for performance and flexibility, 3-(2-aminoethylamino)propyldimethoxymethylsilane emerged—a compound shaped by decades of refinement in organosilicon technology. Scientists at the intersection of materials science and polymer chemistry turned their attention to versatile bifunctional silanes, and the specific reactivity of this diamino-terminated molecule made it stand out. Fast-forward through years of iterative synthesis, analytical breakthroughs, and testing across adhesives, coatings, and composites, and this silane serves as one of the established choices for boosting compatibility between polar and non-polar domains.

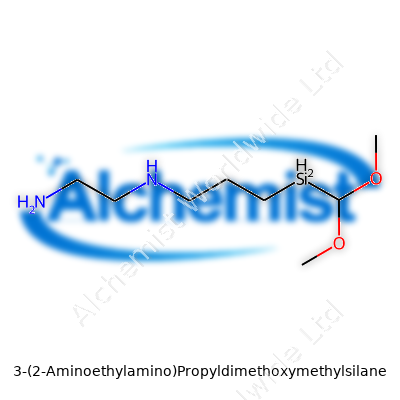

3-(2-Aminoethylamino)propyldimethoxymethylsilane gets its appeal from its chemical architecture—bearing two amine groups plus both methyl and methoxy substituents on a silicon core. The diamino “tail” couples with a reactive silane head, making it a classic example of a bifunctional silane coupling agent. Chemical suppliers often market it for its surface treatment capabilities, especially where epoxy, phenolic, or polyurethane resins need good adhesion to glass, mineral fillers, or metals. This compound addresses the industry’s call for something more than just a generic silane—it adapts to both aqueous and non-aqueous processes and brings a higher level of durability to composite interfaces.

Commercial samples of 3-(2-aminoethylamino)propyldimethoxymethylsilane typically appear as a colorless to pale yellow liquid, bearing a faint amine odor. It comes with a molecular formula of C8H22N2O2Si and a molar mass near 222.36 g/mol. Its density hovers around 0.97–0.99 g/cm³ at 25°C. Boiling points surpass 230°C under atmospheric pressure, but hydrolysis quickly alters the compound in humid air. Two alkoxy groups on silicon make it prone to condensation—forming siloxane bonds during surface treatments. Water solubility and pH stability depend on the hydrolysis of the methoxy substituents, often leading to gel formation in prolonged exposure to moisture.

Suppliers often declare purity above 97%, usually checked by GC or NMR. Typical product packaging includes amber glass bottles or steel drums, labeled according to GHS standards: hazard statements note skin and eye irritation potential, with pictogram codes for corrosive and harmful categories. Lot numbers, batch certificates, and COAs accompany shipments, detailing amine content, water content, and silane assay. Users in industry or research labs reference the IUPAC name or recognize the CAS number 3069-29-2. Documentation always stresses the need for dry storage and resealing after each use to avoid hydrolytic degradation.

Manufacturers synthesize 3-(2-aminoethylamino)propyldimethoxymethylsilane through alkoxysilane functionalization. Starting from methyltrichlorosilane or its equivalents, controlled substitution with methanol under alkaline or acid catalysis yields the dimethoxy-methylsilane backbone. Sequential nucleophilic substitution brings in the propyldiamine side chain. Know-how in dealing with moisture-sensitive intermediates is pivotal during scale-up, and the process demands stainless steel or glass-lined reactors, inert atmosphere, and fractional distillation for purification. Each step depends on precise stoichiometry to curb side product formation, especially as silane moieties often crosslink in the presence of trace water or alcohols.

Once synthesized, 3-(2-aminoethylamino)propyldimethoxymethylsilane shines in its reactivity portfolio. Hydrolytic condensation in water or slightly acidic environments cleaves the methoxy groups, liberating methanol and generating reactive silanols. These bond directly to hydroxyl-rich surfaces like glass, silica, or alumina. Through these Si-O-Si linkages, the diamine chain interfaces with organic polymers, notably via epoxy or isocyanate groups. The two amine functionalities also welcome further modification, such as amidation, acylation, or even selective blocking to tune reactivity toward specific applications or hybrid surface chemistries. In polymer networks or sol-gel systems, the silane’s hybrid structure plays a dual role, reinforcing both the inorganic backbone and the organic crosslinks.

In lab catalogs and inventory sheets, the compound goes by a handful of aliases. The name N-[3-(Dimethoxymethylsilyl)propyl]ethylenediamine shows up frequently, as does its commercial shorthand—DAMO or DAMS, depending on supplier conventions. Other identifiers pop up in patent literature: dimethoxymethylsilane diamine, or just diamino-functional silane. The diversity in nomenclature does cause confusion for new entrants, underlining the need for a solid grasp of structural notation and database search skills.

Facility protocols for 3-(2-aminoethylamino)propyldimethoxymethylsilane start with the basics: gloves, goggles, and good ventilation are non-negotiable. The compound reacts with moisture, so contact with water leads to rapid exothermic hydrolysis and potentially corrosive residues. Spillage on skin or eyes leads to irritation fast; direct inhalation of vapor, especially in poorly ventilated workspaces, triggers respiratory discomfort. Proper storage in sealed containers—cool, dry, dark—ensures product lifespan. Most safety datasheets warn against mixing with acids or oxidizers, with strict guidelines for neutralization and spill clean-up. Waste disposal follows local hazardous waste statutes, given the chemical’s reactivity and environmental persistence.

Users apply this compound widely in adhesives, sealants, and coatings engineering. The surface treatment of glass fibers for composite reinforcement depends heavily on silanes like this; manufacturers enhance the interfacial adhesion to thermosetting resin matrices. In electronics, the silane modifies silica fillers, raises bonding strength in encapsulants, and produces robust corrosion-resistant coatings for metal parts. Even in rubber and tire industries, it’s used to couple silica to elastomeric phases, reducing rolling resistance. Many sol-gel systems, particularly in optical coatings or porous materials, benefit from the compound’s presence, which increases both physical durability and chemical resistance.

Academic groups and private industry push the boundaries with 3-(2-aminoethylamino)propyldimethoxymethylsilane. Surface chemistry research probes new routes for functionalization, looking to anchor catalysts, enzymes, or nanoparticles via the diamine moiety. Innovation in advanced composites leans on the compound for better fiber-matrix load transfer. Its dual-functionality prompts creative linkages with biomolecules, leading to biomedical coatings and diagnostic probe development. I’ve seen collaborative projects between polymer scientists and nanotech experts, hoping to tune hybrid organic-inorganic systems for next-generation electronics, sensors, and energy storage.

Toxicological studies raise flags over both acute and chronic exposures. Irritation to eyes, skin, and respiratory tissues highlights the need for chemical hygiene. Oral and dermal LD50 values remain relatively high compared to more hazardous materials, but sub-chronic data suggest possible sensitization, especially in individuals working without adequate protection. Silane hydrolysis products, especially under improper disposal conditions, present risks to aquatic ecosystems, since methanol and amine derivatives disrupt microbial activity. The science community keeps pushing for better data on bioaccumulation and environmental fate, particularly as silane-modified products enter consumer goods and infrastructure.

Growth in green chemistry trends signals shifts for silane technology. Researchers chase low-VOC alternatives and try to cut down on persistent byproducts, making fully hydrolyzable and biodegradable silanes a focal point. Application in nanostructured materials, especially for flexible electronics or biomedical scaffolds, may redefine what this compound can do. Advances in surface modification could enable more precise targeting of molecular functionality, leading to custom-tailored adhesives and coatings for advanced manufacturing. As automation and data-driven synthesis move forward, the quality and reproducibility of silane-based products look set to rise, bringing new confidence to sectors reliant on dependable, high-performing surface chemistries.

Few people outside of a chemistry lab have ever heard of 3-(2-Aminoethylamino)propyldimethoxymethylsilane. Despite the tongue-twisting name, this compound finds its way into products all around us. I’ve seen it show up most often in industries that deal with surfaces — from electronics to construction. In my own work with materials researchers, its usefulness in enhancing bonds between different substances really stands out.

Imagine a complex device like a smartphone. Plastic touches metal, glass attaches to frames, and coatings protect fragile parts. Getting those materials to stick together and stay bonded isn’t easy. Here is where 3-(2-Aminoethylamino)propyldimethoxymethylsilane comes in handy. It’s what chemists call a silane coupling agent. Basically, the molecule acts like a bridge: one end grabs onto silicon-based things, like glass or certain plastics, while the other connects easily to things like resins, rubbers, or adhesives.

As adhesives improve, they need help in sticking to surfaces that naturally resist glue. This silane “bridge” steps in, allowing glue to hang onto surfaces that would otherwise shrug it off. In construction, I’ve seen it incorporated into adhesives to help glass panels seal tighter to metal window frames. The result: stronger, longer-lasting installations. Reinforced plastics like fiberglass depend on this additive too, so cars, boats, and wind turbine blades don’t fall apart under stress.

Water and electronics don’t mix, yet we carry phones in the rain and take wireless earbuds to the gym. Companies want these products to last despite daily abuse. The chemical helps put a water-repelling layer on surfaces, shielding sensitive electronics from moisture. If you’ve splashed water on a touch screen and watched it bead up, you’ve probably seen this effect at work.

Paint and coatings manufacturers also add it to create finishes that resist fingerprints and smudges. That not only keeps surfaces looking better — it stops dirt and oil from interfering with device performance. Over time, this helps electronics live longer lives and cut down on waste.

As more is learned about silane compounds, safety stays a focus. In poorly ventilated spaces or when mishandled, many silanes can pose health risks. Industry groups and regulatory agencies push for tighter guidelines, with manufacturers investing in safer storage and training for workers. Adoption of best practices has reduced incidents over the past decade, according to occupational safety data.

Support for more environmentally friendly alternatives is growing. Some research teams now explore plant-based silane options or modifications that cut down on volatile organic compounds. There’s movement toward better labeling and traceability—so people handling these chemicals know exactly what they’re working with.

3-(2-Aminoethylamino)propyldimethoxymethylsilane might not have a name that rolls off the tongue, but its job is clear: it makes materials stick together, work longer, and stand up to harsh environments. By tackling water damage, boosting adhesive strength, and streamlining manufacturing, this silane plays a quiet but essential role in industries worldwide.

Peeling a chemical label off a bottle to pour it into a beaker reminds me of growing up and seeing my dad’s warnings scrawled on old gasoline cans. “Don’t touch, wash hands.” It feels like overkill until you walk through an ER on a busy night. Labels carry more than just brand logos; they give direct advice—corrosive, flammable, toxic—that almost nobody enjoys learning the hard way. I’ve watched folks rush, skip reading, pay little attention, then end up searching Google for what to do with a splash to the eye. A clear habit pays off. Make a habit of reading and understanding hazard symbols and handling instructions.

Personal protective equipment sounds clinical, but it’s just armor between you and a risky spill. Thick gloves, sturdy goggles, and lab coats aren’t overcautious; they’re everyday tools. I’ve seen the difference plastic gloves make—one friend got away with only a ruined glove after handling bleach, while another went bare-handed and ended the day at urgent care. Clothes do matter. Wear long sleeves, closed shoes, and skip loose jewelry that might catch.

Messy benches breed accidents. Ever knock over a mystery bottle because someone left it perched by the sink? I’ve cleaned up my share of puddles and spent afternoons sorting unlabeled containers nobody owned up to. Choose a clear, uncluttered workspace. Keep only the materials for your current project on the bench. Quality work starts by wiping down counters, labeling everything, and storing bottles away. From high school chemistry labs to food prep counters at home, a quick tidy-up before and after use stops most headaches from happening at all.

A whiff of ammonia or solvent, even once, sticks in your memory. Those headaches aren’t just bad luck—they’re your body warning you. Proper airflow protects everyone. Open windows or invoke a fume hood. I’ve had to leave rooms before because fumes took over, and I never want to repeat that. If venting isn’t easy, work for short bursts then retreat. Anyone who’s ever gotten dizzy from bleach in a bathroom learns to respect air movement fast.

Pour slow, never rush. Always check for leaks or container damage before starting. Mixing chemicals on a hunch courts disaster. Once, I watched a friend unknowingly mix ammonia and bleach and had to pull him outside coughing. Always add chemical to water, not water to chemical, unless a label says otherwise. Sounds simple, but pressure and inexperience trip up the best intentions. Store containers tightly closed, upright, and far from food or sunlight. Never reuse containers without a full clean.

A safety shower looks intimidating, but knowing the location might save you. The quickest path to the nearest eyewash should be second nature. In case of a spill or splash, water is your friend. Use it copiously. Learn emergency contact numbers, keep absorbent materials nearby, and have a trusted person nearby who knows you’re working with something potent. Chemicals don’t care about intentions, only actions. The right habits make sure work ends with clean hands and a clear head, not a trip to urgent care.

Most folks have glanced at a product label and brushed past the small print about storage. That little section actually shields a product’s quality. My grandfather always stored his garden seeds in a cool, dry place. As a kid, I rolled my eyes, but now I see his wisdom. Storing items the right way, whether it’s food, medicine, or chemicals, makes a big difference in how long they last and how well they work. Temperature swings, moisture, and sun all play into how fast a product can spoil, degrade, or turn useless.

Simple guidelines can save real money and trouble. For example, aspirin breaks down and loses strength far faster in a humid bathroom cabinet than tucked on a shelf in a dry closet. Dairy left out of the fridge gives everyone stomach aches. Some products, like prescription insulin, lose effectiveness if they get too warm or too cold. My own local pharmacy tosses anything that rides outside its safe temperature window. They’ve seen ruined shipments and customers who didn’t read label directions. Safe storage isn’t just about convenience—it keeps us healthy and protects investments.

Improper storage runs up the landfill tally. Spoiled food, expired medicine, and clumped paints or cleaners all become trash, wasting resources used to make and ship them. The UN estimates that a third of all food worldwide goes to waste, much of it from poor storage—foods getting moldy or unsafe before anyone eats them. Better habits protect both the wallet and the environment. Keeping products sealed, away from sunlight, and at a steady, moderate temperature prevents premature spoilage.

Government and industry leaders set storage-related rules for good reasons. Consider medicines: the FDA requires testing at various temperatures and humidity levels before any storage guideline hits a label. This evidence helps people stay safe. Certain products, like chemicals or pesticides, come stamped with storage warnings because the risks go beyond lost dollars—they can create real dangers. Just one poorly stored can of gasoline in a hot garage can end up sparking a fire. In my own neighborhood, a friend’s truck battery exploded during a heat wave after weeks of improper storage; the cleanup cost a fortune and could have turned deadly.

Folks can start by actually reading the label or insert that comes with what they buy. Even small changes, like moving perishable foods to the fridge right after shopping or keeping household cleaners out of direct sunlight, build up over time. Investing a little in proper storage bins, thermometers, or dry pantry containers delivers big returns. At work, companies train staff and post reminders near storage areas—not just for regulatory compliance, but to dodge incidents and save on replacement orders. Lessons learned from real accidents or wasted supplies stick longer than any policy memo.

Knowing the best way to store what we buy seems basic, but it pays off in products that last, health risks we avoid, and less trash in our bins. In my own household, we trimmed grocery bills and stopped tossing ruined pantry items just by labeling shelves and sharing family tips. The more folks take storage advice to heart, the safer, healthier, and more economical our daily lives can get.

3-(2-Aminoethylamino)propyldimethoxymethylsilane, a mouthful even for seasoned chemists, pops up in coatings, adhesives, and specialty chemical projects. This stuff works wonders for boosting adhesion and improving material properties, but it comes with tradeoffs. Based on my experience in university labs, mishandling silane compounds can ruin a day. Gloves dissolved, mystery fumes wafted, and the phrase “just pour it down the drain” never crossed anyone’s lips. It makes sense to respect a chemical that contains both amines and silane functions—elements that can react in clumsy, unpredictable ways with air and water.

Dumping chemicals with active groups—especially ones that hydrolyze and give off volatile siloxanes—never worked out well for anyone. Aminoethyl functional silanes break apart in water, sending fragments into wastewater. Once, after a rushed disposal, a friend found a white gelatinous mess clogging a lab sink. Nobody wants that headache, plus municipal water treatment isn’t built to filter strange organosilicon compounds. Given the way this substance behaves, regular waste bins and the sewer simply aren’t in the picture for honest disposal.

Disposal calls for a cautious, well-informed routine. Sealing any leftover substance in a chemical-resistant container, labeling it with both the full chemical name and concentration, keeps the next person—often a facility manager or hazardous waste contractor—safe and in the loop. Many universities and industrial sites set up hazardous waste pickup days. Labs I worked in kept sturdy chemical waste drums in fume hoods, far from food or open windows, to collect leftovers. Specialty companies like Veolia and Clean Harbors often collect these drums, then send them for incineration in controlled environments. Incineration works here because high temperatures break the silane and amine bonds, chopping the complex molecule into simple gases and ash, with proper filters to handle toxic byproducts. This approach keeps waste from mingling with normal landfill trash or groundwater.

Regulators set down rules, but the habits of those working with chemicals shape outcomes on the ground. Trained staff handling this silane with goggles, gloves, and protective coats face fewer accidents and injuries. Lax routines—like leaving open containers or mixing different chemical groups—invite splatters, surprises, and even costly evacuation drills. I’ve found that routine hazard training makes a massive difference. Quick reference charts, visible cleanup kits, and conversations about near-misses push safety culture forward. Some labs place disposal instructions on the wall above every sink. These reminders help catch those in a hurry or new to lab work, preventing classic mistakes.

Beyond careful disposal, smart purchasing and inventory controls save headaches. Ordering only what’s actually needed shrinks surplus, and so does sharing between teams who use similar materials. My group started biannual chemical swaps, redistributing unopened bottles and outdated stock before expiry. Digital inventory tools give a clear view of what sits unused on the shelf—so project managers don’t forget and order more than necessary. Building these habits—respect, labeling, secure storage, and professional hazardous waste disposal—nudges the chemical world a bit closer to sustainable, safe practice. The costs of proper disposal pale in comparison to the fallout of a contamination incident or a public health scare. These lessons stick with you long after the experiment ends.

Ask someone in a chemistry lab about purity, and you’ll see the attention sharpen. People get picky for good reason. If a compound isn’t pure, the whole point of the experiment or the process can fall apart. Even small changes in purity can throw off biological experiments, cause unwanted side reactions, or affect how a product works in industry. In scientific settings, purity isn’t just about percentages. Folks talk about 98%, 99.9%, and sometimes higher—especially in pharmaceuticals. Each “nine” matters. Contaminants have a way of sneaking up and showing themselves just when you least want them.

I remember waiting for weeks for a shipment that promised 99.99% pure material. A single dust speck in a batch set off alarms and delayed tests. Many labs demand a Certificate of Analysis for each batch. They don’t want to mess around with guesses. It’s part of strict regulations. Sometimes simple mistakes can lead to recalls or spoil big projects.

Let’s talk about what these compounds look like. A lot depends on their exact form. Powders, crystals, or sometimes oily liquids—each tells a story. Chemists expect white or colorless crystals for many highly-pure substances. Off-white or tinted colors often hint at contamination. Some compounds are known to take on certain shapes, like long needles or coarse grains. Smell can also say a lot; strange odors show something’s gone wrong.

Glass bottles used to come hand-labeled with warnings or bragging rights about how clear and fine the product looked. In some chemistry classes, I’d see students eyeing clumped powders with doubt. High-purity materials should flow easily for powders and show clean surfaces for crystals. If there’s a problem, like clumping or caking, moisture or air exposure often played a role. Genuine products rarely look anything but neat.

It’s not just an academic thing. Impure batches cause stress for manufacturers, students, and researchers. Take the world of drug discovery. A new compound with even a hint of unwanted chemical can give misleading results. And in electronics, a speck of impurity can ruin the performance of a whole batch of chips. On the food side, safety rules get strict. Overlooked traces may pose health risks, making detailed checks essential.

I’ve seen teams scramble and lose weeks troubleshooting, only to trace a problem back to the source chemical not being what the label promised. Some supply chains cut corners to save money, but you pay in time and lost trust. Independent quality labs and solid supplier relationships make a huge difference. The old advice of “trust but verify” earns respect here.

Companies benefit from giving more information, not less. Full transparency, proper documentation, and honest communication with users go a long way. Advanced testing—think HPLC, NMR, or mass spectrometry—shouldn’t just be for big labs. Wider access would help all levels, from university labs to hobby chemists, get reliable answers about what’s in the jar.

People should ask questions, not just trust the printed number. It’s worth the trouble to push for high standards and spend a little extra time checking. In every field where compounds matter, a combination of common sense, clear description, and scientific proof keeps progress moving.

| Names | |

| Preferred IUPAC name | 3-[2-(Aminoethylamino)propyl]dimethoxy(methyl)silane |

| Other names |

N-(2-Aminoethyl)-3-aminopropylmethyldimethoxysilane AEAPS Aldrich-440159 Silquest A-2120 N-2-aminoethyl-3-aminopropylmethyldimethoxysilane |

| Pronunciation | /θriː tuː əˈmiːnoʊˌɛθɪl əˈmiːnoʊ ˈprɒpɪl daɪˌmɛθɒksiˌˈmɛθəl ˈsaɪleɪn/ |

| Identifiers | |

| CAS Number | 1069-43-8 |

| Beilstein Reference | 1468561 |

| ChEBI | CHEBI:132754 |

| ChEMBL | CHEMBL1526474 |

| ChemSpider | 16217271 |

| DrugBank | DB08317 |

| ECHA InfoCard | 03a3b344-5b62-403e-81a9-6a09e6b37b7b |

| EC Number | 404-200-9 |

| Gmelin Reference | Gm: 831696 |

| KEGG | C14348 |

| MeSH | D016585 |

| PubChem CID | 10353339 |

| RTECS number | TZ4300000 |

| UNII | W6O7GV71SC |

| UN number | UN3334 |

| CompTox Dashboard (EPA) | DTXSID8040263 |

| Properties | |

| Chemical formula | C8H22N2O2Si |

| Molar mass | 222.39 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Amine-like |

| Density | 0.978 g/mL at 25 °C |

| Solubility in water | Soluble |

| log P | -1.0 |

| Vapor pressure | 0.2 hPa at 20 °C |

| Acidity (pKa) | 10.2 |

| Basicity (pKb) | 6.98 |

| Refractive index (nD) | 1.457 |

| Viscosity | 2 cP |

| Dipole moment | 3.5427 Debye |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 368.6 J·mol⁻¹·K⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes severe skin burns and eye damage. Causes serious eye damage. Harmful if inhaled. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. Harmful if inhaled. |

| Precautionary statements | P261, P264, P271, P272, P273, P280, P302+P352, P305+P351+P338, P310, P321, P332+P313, P362+P364, P337+P313, P391, P501 |

| Flash point | > 108 °C |

| Lethal dose or concentration | LD50 Oral Rat 2413 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 >2000 mg/kg |

| NIOSH | NA括 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 30 mg/m³ |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane 3-Aminopropyltrimethoxysilane 3-Aminopropyltriethoxysilane N-(2-Aminoethyl)-3-aminopropyltriethoxysilane 3-(2-Aminoethylamino)propyltriethoxysilane |