The story of 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane involves more than ticking off dates on a timeline. Silanes started popping up in industrial settings back in the last century, as chemists hunted for new ways to get stubborn materials to stick, bond, and last longer in harsh environments. Over time, researchers opened doors between organic and inorganic chemistry, allowing improved adhesion on tricky surfaces. In those days, specialty silane compounds like this one took shape from both necessity and curiosity, pushed forward by growing demand for functionalized polymers, advanced composites, and coatings that performed under pressure. Looking at how silanes moved from academic labs to factory floors helps us see this compound as another link in a chain of practical discovery, not just a formula on a label.

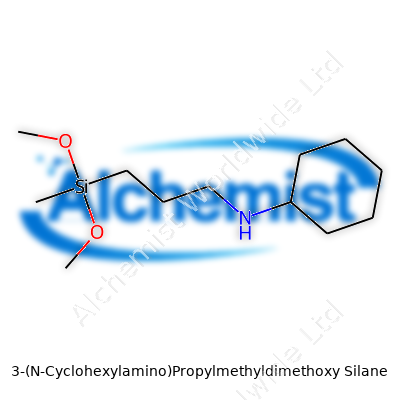

3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane carries a long name, but its function boils down to bridging gaps between different chemical worlds. It packs a propyl chain joined to a cyclohexylamino group, topped off with methyl and dimethoxy silane moieties. This blend proves useful for surface modification, as well as improving bonding where resin meets glass or metal meets polymer. In practice, it acts as a coupling agent, a surface treatment, and a tool for applications where a regular silane can't quite deliver the unique mix of flexibility and reactivity needed. Industries favoring tough, high-value materials—electronics, automotive, adhesives, and coatings—value the versatility and performance edge that comes from compounds like this.

This silane typically appears as a clear to pale yellow liquid with a noticeable but not overwhelming odor. It sticks around in tightly sealed containers, decomposing more quickly when water or air get in, thanks to hydrolysis of those methoxy groups. A density floating close to 0.95–1.05 g/cm³, and a boiling point falling in the range of 230–250°C, shape how it travels through equipment and affects shelf life. Its chemical backbone, built for hybridization, boosts affinity for both polar and non-polar substances. Stability in dry air lasts long enough for storage, but once moisture hits, hydrolysis ramps up, changing its surface activity and sometimes forming sticky residues. These features shape its handling requirements as much as any technical specification.

Reliable sources provide assays for purity, usually aiming above 97%, and spell out water content and color index. Labels must mention proper CAS numbers and product codes, since regulations in North America, Europe, and Asia expect full transparency. Experienced users have learned to check batch certificates and request up-to-date spectral data, such as NMR and IR, before accepting shipments. Flammability, volatility, and chemical stability under defined conditions guide packaging choices. Drum and bottle sizes reflect real-world consumption rates in labs and on production lines, often including tamper-evident seals or argon blankets for more reactive grades.

Making 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane calls for careful stepwise synthesis. Chemists start by combining cyclohexylamine with an appropriate haloalkyl silane, such as 3-chloropropylmethyldimethoxy silane, under controlled temperature. Anhydrous conditions matter; even a trace of water can wreck yields. The substitution reaction bonds the cyclohexylamino group to the propyl chain, spinning off salt as byproduct. Post-reaction workup removes excess amine, washes away inorganics, and strips residual solvents, using distillation or vacuum stripping. The process trades high yields for purity, so secondary purification—distillation or silica gel flash chromatography—may get involved, depending on demands from downstream users.

Chemists who use this silane tend to tinker. The dimethoxy silane part eagerly reacts with water, swapping methoxy for silanol groups. Those silanols bind with hydroxyl-rich surfaces like glass or metals, creating covalent siloxane bonds. The organic side—anchored by cyclohexylamine—takes part in other reactions: epoxy curing, isocyanate crosslinking, or even phenolic resin modification. Branching off from this core molecule, custom silanes can replace the cyclohexyl with other amines, or swap out methoxy groups for ethoxy or other alkoxy chains, tweaking reactivity for targeted projects. The compound’s adaptability lets researchers construct tailor-made interfaces on fibers, fillers, and even nano-structured surfaces.

The compound’s IUPAC name might tie your tongue, but suppliers make things easier. You’ll often see it offered as N-Cyclohexylaminopropylmethyldimethoxysilane, or simply Cyclohexylaminopropyl silane for short. Trade names pop up in catalogue listings, varying with region and manufacturer. You won’t find universal codes outside the CAS number, but careful reading prevents mix-ups with similar organosilicon compounds. This attention to naming keeps everyone grounded, especially when safety and compliance are on the line.

Workplace safety keeps seasoned chemists wary around organosilanes. Breathing in mist or vapor rarely ends well, since exposure causes respiratory and skin irritation. Storage in a dry, cool place wards off accidental hydrolysis, and tightly sealed containers curtail moisture incursion. Spills on skin or eyes call for quick action—safety showers and saline washes. Good ventilation, gloves, goggles, and chemical aprons form the basic gear. Process engineers know from experience that vapor buildup in closed spaces triggers alarms long before concentrations reach regulatory thresholds. Disposal routes must respect both local and international chemical waste guidelines; no shortcuts here. Regular hazard audits and accident drills fit into daily routines for anyone handling reactive silanes.

3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane finds its way into numerous everyday and high-performance products. Glass fiber manufacturers use it to coat reinforcement strands, building bridges between inorganic glass and resin matrices in composites. Electronics assembly lines count on its ability to boost surface adhesion inside microelectronic encapsulants, moderators, and specialty adhesives. Tire factories lean on similar compounds to anchor reinforcing fillers in rubber blends, cutting rolling resistance and boosting tire lifespan. Industrial sealants and paints benefit from improved adhesion to concrete, aluminum, or steel, fighting weather and abrasion with fewer failures over time. In the lab, researchers treat silica, alumina, and pigment surfaces to harness unique chemical, thermal, or mechanical behaviors that standard treatments can't unlock.

Current R&D with 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane covers more ground each year. Multinational firms and academic labs both hunt for silane structures that provide tougher, lighter, or more functional materials. One popular angle: surface functionalization of nanoparticles for responsive coatings or biomedical devices. Another widespread interest: next-generation resins and binders for wind energy blades, lightweight vehicle panels, or smart electronics. Scientists working on greener, low-VOC formulations frequently experiment with silanes to replace older, more toxic monomers. Open access journals list studies on how even small tweaks to the cyclohexyl or silane backbone lead to new ways of controlling interface properties, durability, and compatibility.

Health and safety experts run bioassays on 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane, watching for both acute and chronic effects on humans and the wider environment. Industry reports acknowledge limited but cautionary data on skin and eye irritation, especially in undiluted form. Vapors produce mild respiratory symptoms in animals exposed over extended periods, but studies still wait for more data on long-term inhalation risks in humans. Environmental scientists watch persistence and breakdown products after release, finding that most silanes hydrolyze reasonably quickly, though residues from incomplete reactions remain a concern. Extra care gets paid to downstream products—crosslinked resins, treated composites, or runoff after washing—since ultimate impacts depend not only on parent molecules but their transformation products.

The path ahead for 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane ties into shifts in technology and regulation. Technological leaps in advanced composites, flexible electronics, and green chemistry push demand for more precise tailoring of surface chemistries. Next-generation manufacturing, especially at the interface of digital fabrication and smart materials, keeps silane chemists experimenting with new variants, including multi-functional or stimuli-responsive versions. Governments raising the bar for chemical transparency and environmental respect push manufacturers to fine-tune toxicity profiles and lifecycle assessments. Down the road, expect smarter, safer processing protocols, broader recycling solutions, and chemistries crafted for both higher performance and a lighter footprint. All told, the compound’s legacy continues to stretch well beyond the chemistry bench, shaping everything from the way vehicles last on the road to the lifespan of devices and infrastructure around the world.

In the world of specialty chemicals, some ingredients barely make a ripple, but 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane plays a bigger part than most realize. It belongs to the family of silane coupling agents, which form tight bonds between very different things—like plastics and metals or glass and rubber. This bridging power opens up a surprising number of doors across modern manufacturing.

The stuff that keeps composite materials stuck together often uses silanes like this one. Many tapes, sealants, and adhesives work well only on a limited range of surfaces. A little silane added to the recipe, and those adhesives grab onto glass, metal, and certain plastics with more muscle. Think about how tricky it gets to make window sealants that truly bond to glass panes or how multilayered automotive parts stay fused. Many factories rely on this molecule because it forms covalent bridges that hold tough against heat, water, and stress.

Modern electronics, cars, and even sneakers all use reinforced plastics filled with silica or fibrous materials. The connection between the filler and the plastic matrix often makes or breaks the final product’s performance. The cyclohexylamino group on this silane does more than just cling to glass or silica—it interacts with resin matrices in ways that boost flexibility, durability, and lifespan. Car bumpers, circuit boards, and sports gear with improved shock resistance likely owe something to these unique connections.

Out in the wild, coatings face sun, rain, salty air, and mechanical wear. Paints and coatings with ordinary formulas tend to blister or peel sooner than most buyers like. Adding the right silane delivers an anchor between pigment, binder, and surface, making coatings tougher. Some marine paints, corrosion-resistant industrial coatings, and anti-graffiti finishes benefit from stronger surface bonding—less flaking, better protection.

Few industries demand the purity and reliability of the electronics and optics world. Silane coupling agents can play a quiet, crucial part in fiber optics, LED encapsulation, and circuit assembly. In fiber optic cables, silane treatment helps glass fibers fit better inside plastic housings, guarding against signal loss and mechanical stress. In manufacturing, problems with interface failure often get traced back to poor surface chemistry, so using silane correctly isn’t just insurance—it’s a necessity for dependable performance.

Every specialized chemical brings its own risks. Exposure to organosilane vapors can irritate eyes and lungs. Over the years, I’ve seen some workers skip gloves or ventilation, sometimes leading to rashes or breathing trouble. Following safety data sheets, securing good airflow, and storing chemicals in tight containers reduce these problems. Simple steps protect health and keep these versatile agents working in our favor.

As greener manufacturing grows, companies should look for ways to recycle and recover these silanes rather than treat them as waste. Some labs already test bio-based alternatives or less hazardous blends. Opposing waste and reducing emissions with better capture and reuse can help customers and producers alike. That makes each molecule count for more—both in business and in the environment.

Silanes come with their own quirks. They're reactive with moisture in the air, and that reaction ruins both their effectiveness and anyone’s day in the lab or manufacturing floor. I’ve seen what a single leaky seal can do: a bottle turns cloudy, the cap jams, the whole batch gets tossed. It feels wasteful, expensive, and directly hits the bottom line for both small businesses and big operations.

In my own experience with silane-based materials, keeping things dry and cool spells the difference between progress and headaches. Most manufacturers recommend storing silane in tightly sealed containers, away from moisture, in a well-ventilated spot. Humidity invites trouble, so a desiccated storage cabinet or room with a controlled environment works best.

Direct sunlight turns up the heat and affects the chemical structure too. The last time someone stored a silane container on a sunlit windowsill, things crystallized quicker than anyone expected. That led to delays and unnecessary replacement costs. So a shelf inside, away from the sun and any heat sources, is where silanes thrive.

Studies and technical sheets from leading manufacturers agree: water vapor starts hydrolysis, causing silane products to lose their potent qualities. According to the American Chemistry Council, a temperature between 5°C and 30°C offers a safe window for long-term stability, although specific products may have their own sweet spot.

It’s not just about extending shelf life. Quality and safety play a role too. Silanes often produce small amounts of flammable gases when they interact with air or moist surfaces. A tight seal, low humidity, and a cool setting drastically decrease the risk of fire or harmful fumes.

Companies with robust safety programs invest in dedicated chemical storage fridges for sensitive reagents like silanes. Some firms link their storage rooms to automated alarm systems tracking temperature and humidity, sending a text when things drift outside safe limits. Staff get regular training on handling silanes, including wearing gloves and using goggles simply because a splash or spill isn’t just uncomfortable—it's dangerous.

There is also a growing push for clearer labeling. Simple step-by-step guidance on packaging, not just cryptic chemical icons, gives both professionals and less-experienced staff the confidence to store and handle silanes correctly. Regular checks—weekly if possible—catch slow leaks or developing issues before they turn costly.

Getting serious about proper silane storage means less waste, lower overhead, and safer workspaces. Trustworthy sources—industry white papers, experienced colleagues, technical data sheets—all support this approach. By taking storage conditions seriously, businesses avoid expensive mistakes and protect the health and safety of everyone who comes in contact with silane products.

I remember walking through a chemical plant, the air smelling faintly of something sharp and unfamiliar. 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane sounds like a specialty name pulled out of a Ph.D. thesis, but on the ground, it’s just another bottle labeled with warnings. It’s used to help things stick – glue manufacturers, plastics labs, and coatings teams want what it offers. Yet, no matter how useful, every chemical can turn work upside down if handled carelessly.

Colorless clear liquids don’t always look dangerous, but don’t mistake this one for harmless. Breathing in vapors may leave lungs irritated. Letting it touch bare skin brings itching or burns. Splashing some in your eyes could set off days of problems. The science points to the silane group reacting with water, which includes the moisture on skin or eyes, and doesn’t leave much room for being sloppy. I’ve seen folks skip gloves just to save a minute—usually, they regret it.

Start with fresh gloves. Pull on a clean long-sleeve coat or coveralls before uncapping the bottle. Goggles need to cover all sides, not just the front, so splashes don’t slip in. Actual chemical splash goggles, not the cheap hardware store type, block the stuff from sneaking around corners. A face shield gives extra peace of mind when pouring or mixing. Never count on a regular surgical mask—go for proper respirator masks if high levels could get into the air, since direct inhalation is where things go wrong fast.

Ventilation makes a difference. I’ve worked in stuffy side rooms before where the air turns thick. Running a good exhaust fan means vapor levels stay low. Spills on benches need immediate cleanup, using proper absorbents, and not rags that just push liquids around. All it takes is an elbow bump or a distracted moment to scatter chemicals everywhere.

Don’t leave silanes close to water sources or in the same cabinet as strong acids and bases. Wet storage triggers dangerous reactions. Cool, dry, and well-labeled cabinets cut down on surprises. I date every new bottle when opened, so I don’t end up with a leaking old batch months later. A spill kit for organosilanes should sit within easy reach – sand, inert absorbents, and plenty of waste bags.

Skin contact shouldn’t be ignored. Wash thoroughly with soap and warm water right after contact. Don’t wait or try to “tough it out,” since the irritation grows worse with delays. For eyes, immediately rinse with running water for fifteen minutes minimum, and expect to visit a doctor after. I watched a colleague skip the eyewash, thinking he was fine. He missed a week of work.

Document every incident and every close call. Share lessons learned with new hires instead of saving them for “training sessions.” People remember stories better than rulebooks. Bring up safety reminders often. Nothing kills confidence faster than an accident. Each step away from guidelines adds up, usually ending badly.

Silanes offer a lot to industry, but only if respect for their risk stays sharp. Most problems boil down to ignoring the basics— forgotten gloves, poor storage, rushing through cleanup. Learning from both data and personal slip-ups keeps everyone safer, and at the end of the day, that’s the only reward worth coming back for.

Anyone who’s worked with chemicals in a shop, a lab, or even a garage knows the headache that comes from mixing the wrong stuff together. Once, I watched a colleague pour a solvent into a plastic jug, only to find it dripping onto the floor an hour later. Turns out, that solvent ate right through the container. This kind of thing isn’t some far-off lab disaster—it crops up in everyday workplaces, hospitals, cleaning supply closets, and even kitchens. Chemical compatibility may sound like a technical puzzle, but it makes a real difference in safety and product performance.

Most products get stored, shipped, or pumped using other materials: plastics, rubbers, metals, glues. Some chemicals react, corrode, or break down these materials. Take bleach and ammonia, two common cleaners. Mixed together, they create toxic gas. Acids love to chew up metal. Solvents can warp certain plastics or strip paint. Every material comes with strengths and weak points. Polyethylene bottles work for many cleaning agents because they resist acids and bases. Stainless steel stands up to a slew of harsh substances, but not to chlorides, which can cause it to pit and break down. Even common rubber gaskets may crack if exposed to the wrong oil or fuel.

From food service to chemical plants, people find out fast what happens when compatibility gets ignored. In the food processing world, cleaning agents must not react with piping or tanks, or they risk tainting the food or damaging expensive equipment. In construction, certain sealants and adhesives create headaches by reacting with substrates or giving off fumes that corrode copper pipes. Stories like these push companies to do compatibility testing before rolling out new products or buying storage gear. The EPA and OSHA document plenty of incidents where ignoring this step led to spills, injuries, or fires.

Research by respected organizations, including the National Fire Protection Association (NFPA) and the American Chemical Society (ACS), highlights accidents tied to incompatible chemicals. In 2019, the US Chemical Safety Board reported over 100 incidents linked to poor chemical mixing or storage practices. Materials science supplies mountains of data showing which plastics shrink, crack, or dissolve in various liquids. Manufacturers regularly publish compatibility charts, but these guides help only if people actually read them and apply what they learn on the ground. Simple tests—like leaving a material in contact with a chemical for a set period—can flag obvious problems before a disaster unfolds.

Making workplaces and homes safer starts with better training and clear labeling. Workers and users benefit from plain language that flags risky combinations. No one remembers every single detail, but a well-placed caution sticker or chart on a wall makes it easy to double-check before mixing, pouring, or storing. Builders and buyers can push for more transparent datasheets from suppliers, listing exactly which containers, fittings, and hoses hold up best. It helps to run regular drills or refresher courses, not just file away a compatibility chart in a dusty binder. My own habit—double-checking and running small-scale tests before mixing or storing a new chemical—grew out of those early mishaps. It adds an extra step, but it saves headaches later and keeps everyone safer.

3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane serves as a silane coupling agent in industries like adhesives, coatings, and advanced materials. Like a lot of organosilanes, its shelf life ties closely to storage conditions, container integrity, air exposure, and the environment inside a warehouse. This stuff doesn’t last forever, and treating it like a can of soup on the shelf can lead to costly mistakes. Typically, manufacturers give it a shelf life of about twelve months, provided you keep it in a tightly sealed, original container away from moisture and heat. Even then, the clock starts ticking as soon as it leaves the production line.

Having done some work in a small lab, I’ve seen firsthand how shelf life isn’t some abstract rule but a practical guide. Using silane well past its recommended window often means the science breaks down. Fresh silane tends to look clear or slightly hazy. Once moisture sneaks in, it gets cloudy and sticky, and that signals a serious drop in quality. In most chemistry setups, anything past the shelf life isn’t worth the risk. The product might not hydrolyze properly or could ruin entire batches of expensive resin mixtures, making a simple oversight lead to thousands in lost revenue.

Time, air, and water do the heavy lifting in breaking down silanes. If any water vapor slips past the cap, you can watch the methoxy groups hydrolyze to silanols. Left unchecked, those start sticking together, forming mushy polymers and settling at the bottom of the drum. In real-world terms, that means your coupling agent drops performance, sticks where it shouldn’t, or makes the surface treatment unpredictable. A chemist looking to stretch the shelf life finds out fast that the risk far outweighs the savings. Old silane doesn’t just underperform; it throws off every step in the production chain.

Data from major chemical suppliers points out that 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane keeps best at temperatures under 25°C in areas free from humidity. Fluctuations in temperature and open containers let air and moisture inside, so small leaks or careless transfers shorten the safe period. OSHA and GHS reports back this up, emphasizing clear labeling and vigilant auditing of chemical stocks. If you’ve spent time in a research or manufacturing space, you know someone will eventually grab the oldest bottle if inventory isn’t tight. Training staff to rotate inventory and inspect containers for cloudiness, weird color, or sediment pushes product safety higher.

Purchasing in quantities that match demand helps reduce waste. Regularly updating stock records and marking expiration dates directly on every container makes it easier for anyone in the lab or warehouse to make smart choices. If storage conditions slip out of the recommended zone—even for a few hours—the best option involves pulling the product and running a quality check. Analytical tests like gas chromatography or simple hydrolysis observation still provide the clearest answer about chemical fitness. In busy labs, appointing a chemical officer to oversee stock rotation, staff training, and periodic checks keeps everyone safer and reduces surprises at the bench or production line.

With materials as sensitive as this silane, taking short cuts just isn’t worth it. Effective shelf life management saves money, keeps people safe, and makes the final product more reliable. That lesson stuck with me after a ruined batch cost several days of productivity and forced the team to rethink storage policies. By giving attention to how and where chemicals age, teams build real trust in every reaction and every finished good.

| Names | |

| Preferred IUPAC name | N-cyclohexyl-3-(dimethoxy(methyl)silyl)propan-1-amine |

| Other names |

Z-6679 SILANE, 3-(N-CYCLOHEXYLAMINO)PROPYLMETHYLDIMETHOXY 3-(N-Cyclohexylamino)propylmethyldimethoxysilane |

| Pronunciation | /θri ɛn saɪ.kloʊˈhɛk.sɪl.əˌmiː.noʊ ˈproʊ.pɪl ˈmɛθ.əl daɪˈmɛθ.ɒk.si ˈsaɪ.leɪn/ |

| Identifiers | |

| CAS Number | 13822-56-5 |

| Beilstein Reference | 4-02-00-03041 |

| ChEBI | CHEBI:64237 |

| ChEMBL | CHEMBL2117502 |

| ChemSpider | 18710568 |

| DrugBank | DB16771 |

| ECHA InfoCard | 32be6c38-5da9-4ea6-b1fa-44e15f2fa221 |

| EC Number | 602-212-3 |

| Gmelin Reference | 82816 |

| KEGG | C19236 |

| MeSH | 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane" does not have a specific MeSH (Medical Subject Headings) term assigned to it. |

| PubChem CID | 10476592 |

| RTECS number | GZ1525000 |

| UNII | S2UL1M0BKW |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | urn:epa:comp_tox-dashboard:DTXSID30892324 |

| Properties | |

| Chemical formula | C14H31NO2Si |

| Molar mass | 319.54 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Amine-like |

| Density | 0.96 g/mL at 25 °C (lit.) |

| Solubility in water | Slightly soluble |

| log P | 2.6 |

| Vapor pressure | 0.9 hPa @ 20 °C |

| Acidity (pKa) | 14.7 |

| Basicity (pKb) | 4.57 |

| Magnetic susceptibility (χ) | -7.71×10^-6 cm³/mol |

| Refractive index (nD) | 1.4500 |

| Viscosity | 15 cSt |

| Dipole moment | 3.4092 D |

| Pharmacology | |

| ATC code | There is no ATC code assigned to '3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane'. |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07, GHS05 |

| Signal word | Danger |

| Hazard statements | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. Harmful to aquatic life with long lasting effects. |

| Precautionary statements | Precautionary statements: P261, P264, P271, P272, P280, P302+P352, P333+P313, P362+P364, P321, P501 |

| Flash point | 83 °C |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 2413 mg/kg |

| NIOSH | NA |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 3-(N-Cyclohexylamino)Propylmethyldimethoxy Silane: Not established |

| REL (Recommended) | 2 mg/L |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Trimethoxypropylsilane 3-Aminopropyltrimethoxysilane 3-(N-Ethylamino)propylmethyldimethoxysilane N-cyclohexylaminopropyltrimethoxysilane N-Phenylaminopropylmethyldimethoxysilane |