Chemists started exploring organosilicon compounds in the early 20th century, working to bridge the gap between mineral and organic chemistry. Soon after Eugene Rochow and Richard Müller made commercial routes to methylchlorosilanes available in the 1940s, researchers carved out new classes of intermediates. Methylpropyldichlorosilane arrived as a result of persistent efforts to diversify halosilanes for the growing silicone market. Largely overshadowed by its cousins methyltrichlorosilane and dimethyldichlorosilane, this compound spent decades as a specialty building block tucked into niche processes. Only as demand for novel siloxanes and surface treatments increased did methylpropyldichlorosilane step into the broader picture.

Commercial methylpropyldichlorosilane comes as a colorless to pale liquid, carrying a pungent odor familiar to anyone who has worked with alkylchlorosilanes. It bridges two simple alkyl chains—one methyl, one propyl—attached to a silicon atom bonded to two chlorine atoms. This chemical finds its home mostly in specialty silicone polymers, resins, and as a hydrophobic treatment for advanced materials. Most labs and industrial users recognize it as a highly reactive monomer, ready for downstream siloxane synthesis or site-specific chemical modification.

Methylpropyldichlorosilane offers a boiling point near 135°C at atmospheric pressure, slightly higher than dimethyldichlorosilane. This comes from that n-propyl group, which stabilizes volatility without making things sluggish to evaporate. Its density clocks in close to 1.01 g/cm³, making it manageable in weighing and dispensing for industrial operations. Smelling it brings an immediate warning to your senses, a sign that hydrolysis and the release of hydrogen chloride aren't far off. Its miscibility favors organic solvents—toluene, hexane, and ether take it up easily. It keeps mostly clear in storage when kept away from water, but a stray drop in a humid atmosphere sends up clouds of hydrochloric acid fumes in seconds.

Reliable methylpropyldichlorosilane in the market meets purity standards above 98%. Chlorine content and non-volatile matter show up on product COAs, and even a quarter-percent of high-boiling siloxane impurity brings headaches for downstream users. The product lands in properly sealed, lacquer-lined steel drums or amber glass bottles, bearing GHS-compliant hazard labels. It falls under UN 2987 for transport, demanding ventilation, eye protection, and acid-resistant gloves at all times. Only in recent years did labeling move toward QR-tracked inventory systems, which now tie batch origin, test results, and safety documentation directly to each container.

Industrial producers usually prepare methylpropyldichlorosilane by reacting methylchlorosilane streams with propyl chloride in the presence of copper-based catalysts. Some still prefer the direct process—passing methyl chloride and propyl chloride over a silicon-copper alloy at temperatures just north of 250°C. This route boosts selectivity but chews up catalysts quickly. Small-scale synthesis may substitute Grignard reagents, allowing for more controlled introduction of the alkyl groups in research batches. Each process step carries strict demands for exclusion of water and oxygen, since a single leak transforms valuable feedstock into difficult-to-handle silicic acids.

Methylpropyldichlorosilane springs to life as soon as it hits water or alcohols, splitting its silicon-chlorine bonds in rapid hydrolysis. This reaction tosses out protons and hydrochloric acid, creating a steady string of silanol groups. Chemists use this in controlled conditions to build siloxane chains or crosslinked resins, often trapping reactive intermediates with organic bases or tertiary amines to avoid HCl side reactions. Alkyl substitution opens the door to further functionalization—epoxides, amines, and even fluoroalkyls link in, producing tailored silanes for coatings, adhesives, or composite surface treatments.

Methylpropyldichlorosilane shows up under several names in catalogs and MSDS sheets: n-propylmethyldichlorosilane, dichloro(methyl)(propyl)silane, and its CAS number, 18171-19-0. Sometimes the order flips—propyldichloromethylsilane pops up, or suppliers add prefixes indicating the chain’s iso-configuration. Most industrial users stick with the straightforward abbreviation, MPDCS, to skirt confusion in inventory and documentation. Specialty fragments or derivatives—like n-propyltrimethoxysilane, birthed from MPDCS—carry their own designators, but trace back to the same parent molecule.

Handling methylpropyldichlorosilane brings a risk set that experienced chemists respect at all times. Direct skin contact leads to rapid chemical burns as hydrolysis starts upon contact with moisture on skin. Breathing its vapors irritates lungs, and even a whiff stings the nose and throat. Proper PPE means rubber gloves, goggles, and strong local exhaust. All transfers happen in a chemical fume hood, using inert gas overlays for container openings. Spill response goes beyond lab aprons—a soda ash solution sits on standby to neutralize any runoff, followed by careful collection of residual residues. Emergency protocols stress immediate irrigation in case of eye or skin exposure, and bringing safety showers close to the work area helps anyone caught by accident. Facility audits check ventilation rate, container compatibility, and training for every worker on handling chlorosilanes.

Most methylpropyldichlorosilane heads for custom silicone polymer production. Its combination of methyl and n-propyl groups tunes the properties of final siloxane materials—some aim for flexibility, others for improved hydrophobicity on glass, ceramics, or stone. Small-scale electronics production draws on its ability to install robust water-repellent surfaces on semiconductors or printed circuit boards. In fiber technology, surface treatments with MPDCS improve dye migration resistance and block water absorption. Dental impression materials and specialty adhesives have quietly benefited from its introduction, leveraging its balance of reactivity and organic compatibility. Even art conservationists, facing crumbling stone, have found new life by protecting surfaces with derivatives of this silane, reducing weathering without altering visible texture.

Research around methylpropyldichlorosilane over the last decade has pivoted away from routine polymer synthesis toward nanostructured surfaces and targeted chemical modifications. Labs exploring hybrid siloxane-organic polymers test MPDCS as a precursor for branched or dendritic architectures. Some breakthroughs in anti-fouling coatings relied on this molecule’s unique alkyl-silicon backbone, slowing the buildup of barnacles on ship hulls. Environmental scientists try functionalized MPDCS-based materials for oil-water separation, with early results showing durable, washable recovery rates above 90%. The molecule’s combination of volatility and selective reactivity underpins a steady flow of new patents in biomaterials, specialty fluids, and lightweight construction composites.

Workplace exposure studies focus on the irritancy and acute toxicity of methylpropyldichlorosilane. Inhalation at moderate concentrations produces rapid inflammation, with test animals developing bronchial lesions within hours at doses above 100 ppm. Chronic exposure data trails behind, but concerns over possible organosilicon bioaccumulation lead to strict exposure limits: typically, occupational environments cap airborne levels below 1 ppm. Animal studies do not show clear evidence of carcinogenic risk, but the cleavage product, hydrochloric acid, brings corrosive effects that drive most risk management policy. Developmental toxicity and reproductive health data remain sparse, pushing for more long-term studies—especially for workers in silicone manufacturing plants.

Most see methylpropyldichlorosilane remaining a specialty tool, growing along the rising demand for engineered silicone surfaces and hydrophobic barriers. Next-generation electronics will need better dielectric coatings, where MPDCS-based siloxanes offer tunable insulation at micro and nano scales. Material scientists keep looking for new ways to extend MPDCS-derived treatments onto metal-organic frameworks and hybrid materials, improving everything from self-cleaning windows to desalination membranes. New regulatory pressures calling for safer processing of chlorinated intermediates push researchers toward greener, catalytic routes or recyclable solvents for handling and hydrolysis. Sustainability takes center stage—less energy-intensive syntheses and new recycling pathways may shift the economics of niche silane intermediates. Unless the market veers away from silicon-based chemistry entirely, methylpropyldichlorosilane will continue to punch above its weight in labs and factories that value specialty performance and chemical versatility.

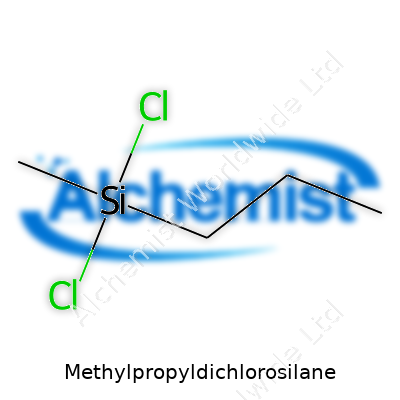

Methylpropyldichlorosilane carries the chemical formula C4H10Cl2Si. Anyone looking at its basic structure sees a silicon atom at the core. Two chlorine atoms stick directly onto silicon, while a methyl group (CH3) and a propyl group (C3H7) fill out the rest of the positions. In line-form, the formula comes out as CH3SiCl2C3H7. Visualizing the skeletal formula, picture silicon surrounded by two chlorines on either side and branching organic groups on the others. This mix brings together the stubbornness of inorganic chemistry and the resourcefulness of organics.

Materials like methylpropyldichlorosilane rarely turn up in the news, yet their impact touches plenty of familiar products—from smartphone coatings to construction materials. The molecule’s structure sets up its role as a building block in making siloxane polymers and silicone fluids. The two chlorine atoms aren’t just fillers; they give the compound a kick for further reaction, letting it link up with other ingredients. Silanes like this show up in labs and factories, acting as connectors that let science move from greasy glassware to sturdy, water-resistant consumer goods.

Anyone who’s worked with dichlorosilanes knows they deserve respect. Chlorine atoms, while great for reactivity, also mean the compound demands careful handling. You spill it on a bench, you smell hydrochloric acid vapor before you even get a whiff of silicon. That alone pushes for strong ventilation, chemical gloves, and real focus in the lab. Industrial users know these hazards, so they plan with protective gear, fume hoods, and robust protocols.

With so much focus on sustainability, it helps to see where these molecules lead. Methylpropyldichlorosilane, thanks to its reactive sites, helps produce silicones with specialized properties. Silicone sealants, lubricants, and coatings start out from silanes like this. Without carefully designed chemicals, we’d end up with products that flake, crack, or simply give out under stress. In the electronics sector, the ability to fine-tune surface chemistry supports reliability in harsh conditions, including damp, heat, and shock.

Working with chlorinated silanes isn’t all smooth sailing. The production brings environmental costs, particularly releases of hydrogen chloride. Continuous improvement in ventilation, scrubbing systems, and closed-reactor setups has cut problems like those down in modern plants. Researchers continue to search for routes to create silanes with less waste and lower emissions, often by recycling or switching to greener feedstocks. Down the line, advances in catalysis could trim both cost and impact.

Quality control stays essential, both for user safety and product performance. Analytical testing tracks purity and chloride content, leading to safer and more reliable end results. Over time, stricter standards and new handling methods will keep pushing safety and environmental goals forward, giving both producers and users better results.

Methylpropyldichlorosilane doesn’t appear in the spotlight often, but anyone who has spent time in a lab or worked near an industrial plant for specialty chemicals will know how important these silane compounds can be. This chemical acts as a valuable building block, transforming the way many materials handle moisture, heat, and ordinary wear and tear. From my own years working alongside chemical engineers, certain applications keep cropping up wherever there’s a need for durable surface treatments or precise industrial processes.

The backbone of silicone resins and rubber often includes silanes like methylpropyldichlorosilane. In silicone elastomer manufacturing, this compound helps anchor organic side chains to the silicon backbone. The result? Flexible, heat-resistant, and long-lasting rubbers and resins. Think about bakeware that takes hot oven temperatures, the insulating foam protecting electrical wires, or medical tubing that needs to flex without breaking down. High purity silanes make these things possible, and they start transforming at the production facility with tightly controlled reactions and rigorous quality checks at every stage.

Plastics, glass, and even ceramics get a boost from treatments involving specialized silanes. Methylpropyldichlorosilane, in particular, joins the workflow in functionalizing surfaces. Coating glass fibers or plastics with these agents helps them stick better within composite materials—this is key in automotive and aerospace fields where lighter and tougher materials are always in demand. A better bond throughout the material means safer cars and more fuel-efficient planes. From discussions with composites engineers, skipping the right silane in production makes for brittle parts and substandard results. Using methylpropyldichlorosilane in this process creates products that stand up to tough standards without breaking apart under pressure.

Methylpropyldichlorosilane also finds its way into sealants and adhesives that need to last through exposure to water, sunlight, and constant stress. Its chemical structure offers strong cross-linking abilities, which keep construction sealants and manufacturing adhesives from peeling off or breaking down easily. In home improvement and industrial jobs alike, these silane-modified products keep buildings weatherproof, appliances running safely, and machine parts sticking together where simpler glues would fail.

While these applications improve everyday life, handling methylpropyldichlorosilane brings its own set of challenges. This is a highly reactive chemical. Anyone mixing or applying it needs proper protective gear—industrial suppliers don’t skimp on PPE recommendations. I remember safety briefings that stressed using well-ventilated spaces and keeping a close eye on spill procedures. According to the European Chemicals Agency, even a small leak or accidental exposure can lead to skin, eye, or respiratory irritation. Transparent labeling and solid worker training can keep people safe while maximizing the benefits of this chemistry.

Environmental rules keep tightening, asking for more sustainable ways to manufacture and dispose of chemicals like methylpropyldichlorosilane. Companies work on new production methods to reduce waste and energy use. At trade expos, I’ve seen industry leaders talk about shifting toward greener feedstocks and closed-loop systems. These solutions take time and investment, but the progress means products made with this silane compound can keep getting safer and more environmentally friendly, meeting both market demand and public trust.

Anyone handling methylpropyldichlorosilane learns quickly it’s not a chemical for shortcuts. Splash a little water near it, and this stuff spits out hydrochloric acid gas—a slap in the face for your skin, eyes, lungs, and anything else in range. Spend a day working near an unsealed drum and the sharp, choking cloud lets you know this isn’t your average solvent. I’ve seen folks turn casual with chlorosilanes, thinking gloves and a pair of goggles is enough, but this is exactly where bad accidents start.

Controlling exposure calls for gear that holds up against acids and fumes. Regular rubber gloves degrade fast. I once noticed pinholes in a pair after a couple of hours of work. Nitrile or butyl rubber gloves hold up better. Full face shields go hand-in-hand with goggles—one’s not worth much without the other. Use flame-resistant lab coats, because it reacts with water and alcohol, sometimes giving off enough heat to ignite. Good respirators matter too. I use one with an acid gas cartridge. If the air smells sharp or you start to cough, take it as a warning sign.

Never let this chemical mingle with water, which can hide in dirty glassware or lines. Dry glassware ends up being your most valuable ally here. I always run checks for moisture and use nitrogen or dry argon as a blanket when transferring the liquid. Small accidents can escalate: a bit of water can shoot hydrochloric acid into your breathing space. Ventilated hoods pull fumes away, but sometimes even the hood can’t keep up if you spill a lot at once. Drip trays help collect any leaks. Proper storage means tightly sealed containers, clearly labeled, and kept in dry cabinets. I remember a scare when a careless coworker put the bottle near a vent, humidity seeped in, and the next worker faced a nasty surprise.

Accidents don’t wait for you to be ready. Emergency showers and eye wash stations save eyes, skin, and lungs from long-term harm. In my lab, we keep calcium gluconate gel ready in case of skin contact, because washing alone doesn’t stop the burn from hydrochloric acid. It takes a minute for panic to set in, so practice emergency routines until everyone moves smoothly. After a spill, plenty of absorbent pads and neutralizer speed up the cleanup. Bags for hazardous waste stand by for rags and pads. If it catches fire, dry sand puts out the flames without reacting; never use water.

Clear training makes all the difference. New hires shadow experienced techs instead of learning chemicals by the book alone. This keeps hard-learned habits alive—checking PPE, double-sealing every cap, keeping a close eye on peers who might get careless. Industry data from the U.S. Chemical Safety Board shows that improper storage and poor training rank among the top causes of chemical plant injuries. Regular drills and honest discussions lower risk much more than compliance checklists ever could.

Handling methylpropyldichlorosilane never feels routine. Layers of protection, right gear, moisture-free handling, and practiced responses all build safety into daily work. Hard-earned habits paired with sound training protect people better than rules on paper. I believe these lessons work across labs and industries—respect the chemical, and it repays you with a safer shift.

Many chemicals come with pages of instructions and warnings, but Methylpropyldichlorosilane stands out for a simple reason – this stuff reacts fiercely with water and most organic materials. I’ve seen too many workplace incidents involving improper storage of reactive silanes, with each one driving home the point that you overlook these rules at your own peril. Silanes like this one release hazardous, corrosive fumes if even a tiny bit of moisture sneaks in. It doesn’t just ruin the product. It quickly puts people at risk for burns, breathing trouble, and, if things spiral, much worse.

Storing Methylpropyldichlorosilane calls for extra diligence. Keep it in a cool, dry place, away from direct sunlight and sources of heat. High temps accelerate all kinds of unwanted reactions. I’ve seen containers distort when staff stacked them too close to steam pipes or sun-facing windows. These mishaps cause lids to loosen and let air creep in. To prevent this, aim for a consistent temperature, something in the 15–25°C (59–77°F) range. Swings in either direction weaken both the package and the product.

Humidity is the silent troublemaker. Even a little bit in the air spells disaster if it gets past a loose cap. Every time a container is opened, humid air tries to rush in. This is why chemical engineers recommend low-humidity storerooms and tightly sealed containers. Desiccants help, but they shouldn’t be the only line of defense. One veteran plant manager I met swore by double-sealing and using dry nitrogen for blanketing containers – an extra expense, but it really stops the moisture in its tracks.

Not every warehouse has the luxury of ample space, but crowding flammable acids together invites trouble. Methylpropyldichlorosilane gives off hydrogen chloride gas if it comes into contact with water or certain bases. In some explosions I’ve read about, all it took was a minor spill or a leaky roof to set off a chain reaction. Don’t put it near strong oxidizers, acids, or other materials it could react with. Always inspect storage areas for any signs of leaks, corrosion, or faulty labels. That simple habit stops half the accidents before they ever get serious.

Original, corrosion-resistant containers give the best results. People sometimes get lazy and transfer silanes into jugs or drums that weren’t made for harsh chemicals. That shortcut puts everyone at risk, not just the person handling the barrel. Good packaging earns its keep when trouble strikes. Keep the right spill kits, fire extinguishers, and personal protective equipment within easy reach. Proper training makes all the difference, too. I listen far more closely to advice from someone who’s handled a silane spill than a cold checklist.

Big incidents grab headlines, but most chemical injuries stem from small lapses – a distracted worker, a short-cut, a missed inspection. Company after company finds out the hard way that sloppiness with highly reactive chemicals costs more than any corrective measure. Good storage practices keep people, property, and product out of harm’s way. I always tell new techs: treat every drum or flask as if it could cause trouble, because one day, it probably will.

Methylpropyldichlorosilane gets used for all sorts of silicone chemistry work, from coatings to making fancy sealants that keep water and grime where they belong. A lot of folks who handle this chemical might not realize how nasty it gets if it ends up somewhere it shouldn’t. We’re talking clouds of hydrogen chloride gas and corrosive byproducts the second this stuff touches moisture. That’s not just a lab headache—stuff like that puts workers, sewer crews, and neighbors in the direct path of some real health risks.

I’ve seen a drum of this compound get opened in a storeroom that didn’t have proper ventilation. It only took a few drops on the floor before the room filled with choking fumes. The lesson never left me: you mess with this chemical, sloppy habits come back to bite hard. Burned lungs or ruined equipment—both expensive mistakes. Nobody wants to trace a sewer backup to some forgotten bottle of reactive industrial waste.

Some small labs think pouring leftover methylpropyldichlorosilane into the sink gets rid of the problem. It just creates a chemical hazard somewhere downstream, not to mention a legal and ethical mess. The EPA treats chlorosilanes as hazardous waste for good reason. Ignoring that empties trouble into groundwater, pipes, and eventually, into food or drinking water.

The right step starts with a trained team. Confined disposal means handing material over to licensed hazardous waste handlers. They collect, label, and track every drop from your bench to an incinerator or chemical processor that handles halogenated silanes. I’ve worked with outfits that give proof of safe destruction—like a receipt for peace of mind.

Don’t let staff handle open bottles unless the place has a fume hood and splash protection. PPE isn’t some box-ticking exercise; it only works if gloves, goggles, and aprons match what the chemical throws at you. If something spills, neutralizing the acid byproducts right away keeps a minor cleanup from turning into a full evacuation.

Folks sometimes grumble at the price tag attached to hazardous waste disposal. Honestly, lawsuits and hospital bills run higher. Chemical management pays back every time you avoid an accident. Track every shipment, use as little as possible, and keep better records than the minimum law expects. When drum labels fade, problems grow.

Any business handling these chemicals should hold tight to clear protocols, not cut corners. Sharing knowledge around the shop keeps the new hires alert and the seasoned pros honest. I've been in places where one good safety meeting prevented months of sick leave. No siloed operations, no guessing—only teamwork and continuous reminder of the risks and best practices.

Out in the field, innovation counts. Some companies hunt for silanes that deliver performance with less toxicity or easier disposal. Where options exist, switch to green chemistry alternatives. If everyone chooses safer roads, pressure mounts on suppliers to produce cleaner products.

The headline here: Methylpropyldichlorosilane doesn’t belong in the trash, the drain, or the open environment. Professional handling, trusted partners, and a culture of accountability keep people safe. Nobody remembers a safe day—unless you’ve worked through what it looks like when safety falls apart.

| Names | |

| Preferred IUPAC name | Chloro-dimethyl(propyl)silane |

| Other names |

Dichloromethylpropylsilane Methyl-n-propyldichlorosilane Methylpropyl silicon dichloride |

| Pronunciation | /ˌmɛθɪlˌprəʊpɪlˌdaɪˈklɔːrəˌsɪleɪn/ |

| Identifiers | |

| CAS Number | 13822-56-5 |

| Beilstein Reference | 1691126 |

| ChEBI | CHEBI:88275 |

| ChEMBL | CHEMBL1901177 |

| ChemSpider | 18702158 |

| DrugBank | DB14096 |

| ECHA InfoCard | 03-2119980488-37-0000 |

| EC Number | 213-467-1 |

| Gmelin Reference | 74137 |

| KEGG | C18539 |

| MeSH | D017238 |

| PubChem CID | 11410 |

| RTECS number | VV8575000 |

| UNII | ROD7F08CJG |

| UN number | UN2536 |

| CompTox Dashboard (EPA) | DTXSID8036795 |

| Properties | |

| Chemical formula | C4H10Cl2Si |

| Molar mass | 176.10 g/mol |

| Appearance | Colorless liquid |

| Odor | Pungent |

| Density | 1.055 g/mL at 25 °C |

| Solubility in water | Decomposes |

| log P | 1.8 |

| Vapor pressure | 3.0 hPa (20 °C) |

| Acidity (pKa) | pKa = 5.3 |

| Basicity (pKb) | Strongly basic (pKb > 4.5) |

| Magnetic susceptibility (χ) | -62.5 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.432 |

| Viscosity | 0.68 mPa·s (25 °C) |

| Dipole moment | 1.66 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 322.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -198.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1510.9 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS05 |

| Signal word | Danger |

| Hazard statements | H225, H314, H335, H331 |

| Precautionary statements | P210, P220, P234, P260, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P308+P311, P363, P370+P378, P403+P233, P501 |

| NFPA 704 (fire diamond) | 3-2-1-W |

| Flash point | 30 °C (86 °F) - closed cup |

| Autoignition temperature | 300 °C (572 °F) |

| Explosive limits | Explosive limits: 1.1% - 8.8% |

| Lethal dose or concentration | Lethal dose or concentration: LD50 (oral, rat) 1800 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: 1800 mg/kg |

| NIOSH | ST2100000 |

| PEL (Permissible) | PEL (Permissible exposure limit) for Methylpropyldichlorosilane: Not established |

| REL (Recommended) | 0.1 ppm |

| IDLH (Immediate danger) | IDLH: 5 ppm |

| Related compounds | |

| Related compounds |

Trimethylchlorosilane Dimethyldichlorosilane Methyltrichlorosilane Propyltrichlorosilane Ethyltrichlorosilane Vinyltrichlorosilane |