N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane has roots reaching back to the growing age of organosilicon chemistry in the postwar period. In the 1940s and 1950s, chemists went searching for ways to bridge organic and inorganic worlds, looking to tie molecules to surfaces or to bring resilience and flexibility to simple silicate materials. By the 1970s, specialty silanes like this one let new industries thrive, from glass fiber composites in construction to computer chips in electronics. Each generation of researchers built processes that let these coupling agents work better, last longer, and deliver more targeted surface modifications. The commercial production of versatile diamino silanes like this offered precision handling and improved compatibility in adhesives, coatings, and advanced hybrid materials.

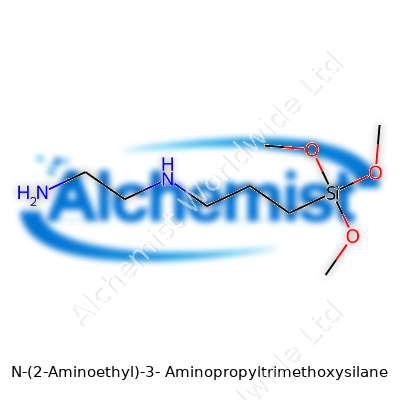

N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane stands out for its dual amino functionality. Its structure features both a primary and a secondary amine, connected through a flexible alkyl chain holding a silyl group at one end. The silane section functions as a powerful anchor, hooking into siliceous surfaces such as glass, minerals, and oxidized metals. The amines reach outward, creating points for further chemical attachment. Industries count on these molecules when they need to toughen resin bonds to glass, improve pigment dispersal, or tweak surface chemistry for high reactivity or compatibility. A clear, low-viscosity liquid handles easily, blending smoothly into formulations from epoxies to sol-gels.

This silane typically presents as a colorless to pale yellow fluid. It gives off a faint amine odor familiar to anyone working with amino silanes or basic amine solutions. Its molecular formula, C8H22N2O3Si, translates to a lightweight molecule with a molecular weight around 222 g/mol. Soluble in alcohol, toluene, acetone, and even water under acidic conditions, it quickly hydrolyzes to silanols in the presence of moisture. The trimethoxysilyl group proves reactive toward hydroxylated surfaces, anchoring firmly by forming Si–O–Si bonds. The amines deliver nucleophilicity, making the molecule useful in further syntheses and modifications.

Pure N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane usually ships with a purity exceeding 97%. Handling involves tight moisture exclusion, as hydrolyzed silane rapidly self-condenses, forming gels or films. Bottles carry tightly sealed lids, often under nitrogen or argon atmospheres. Supplier labels highlight its CAS number 1760-24-3, emphasizing the presence of both primary and secondary amine groups. Storing below 25°C extends shelf life and preserves reactivity. Manufacturers supply batch-specific certificates showing water content, color, density (about 1.01–1.04 g/cm³ at 25°C), and refractive index for quality control.

Production takes advantage of the classic Grignard reaction, where a protected aminopropyl chloride or bromide reacts with trialkoxysilane and an ethylenediamine source. Careful conditions knock down side reactions and purify the dual amine product. Large-scale synthesis demands strict exclusion of water and oxygen. Once produced, fractional distillation pulls the desired compound from possible byproducts, delivering a silane with clean amine groups ready for use. Many researchers still experiment with alternate synthetic tricks, hunting for simpler or greener routes for bulk manufacture.

Surface chemistry loves this silane thanks to its ability to forge covalent bonds between organic resins and inorganic surfaces. When spread onto glass or silicon dioxide, the trimethoxysilane groups hydrolyze and polymerize with surface hydroxyls, creating a dense, bonded monolayer. The amine end keeps reacting—with epoxy groups, isocyanates, acids, or functionalized nanoparticles—for further property tuning. In sol-gel synthesis, this silane joins cross-linked matrices, lending strength and flexibility. Using different reaction schemes, researchers can introduce tailored functionalities by protecting or modifying one or both amines, sometimes linking small biomolecules or catalyst sites onto surfaces.

Common trade and chemical names for N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane include APTMS and AEAPTMS. Several large suppliers market it under unique brands, but chemists often reference it simply as 3-(2-aminoethylamino)propyltrimethoxysilane. Related compounds swap the methoxy groups for ethoxy groups, but this trimethoxy derivative reigns supreme for its fast reactivity and reliable performance in silanization.

Working with N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane brings real safety considerations. Amines act as skin and eye irritants, so gloves and facial protection stay essential. Vapors can cause respiratory discomfort, especially in confined or poorly ventilated spaces. Because the silane hydrolyzes with moisture, spills create slippery surfaces and strong-smelling fumes. Proper chemical hygiene means high-quality ventilation, secure storage, and immediate cleanup. Many labs keep formal safety datasheets on hand, emphasizing first aid and accidental exposure protocols. As with all reactive silanes, waste gets segregated for specialty disposal to prevent environmental contamination.

Demand for this silane explodes in composites and coatings. Glass fiber reinforced plastics use APTMS as a coupling agent, where it boosts strength by tying glass fibers to resin matrices. Epoxy and polyurethane adhesives draw on its amine groups for quick cross-linking and higher peel strength. In electronics, APTMS enables controlled functionalization of silicon wafers before integration into microelectronic circuits or biosensors. Nanotechnology research often deploys the silane to immobilize enzymes, antibodies, or nanoparticles onto glassy surfaces for lab-on-a-chip diagnostics. Its use spreads further into corrosion-resistant coatings, pigment treatment for improved dispersion, and the preparation of catalyst supports.

Through decades of research, chemists keep returning to this silane as a benchmark for new functionalized surfaces. Recent studies explore how fresh synthetic approaches or greener solvents can lower cost and waste while delivering purer product. Research teams publish reports on its role in targeted drug delivery, where its amine groups allow for selective conjugation of biomolecules. Other labs explore APTMS’s action in sensing technologies, as its amine-rich surface modifies electronic and optical behavior in sensors. Continued research seeks to widen the list of compatible polymers and develop new composite systems balancing mechanical and chemical performance.

No one should ignore toxicity when scaling up use. Studies find that neat APTMS acts as a skin, eye, and respiratory irritant. Chronic exposure in animal models signals that primary amines may cause slow tissue damage if handled recklessly. Aquatic toxicity also gets notice, with tests showing silanes can impact aquatic organisms if released untreated. Ongoing research strives to clarify the fate of these compounds in waste streams, ensuring compliance with environmental regulations. In practice, rigorous training and proper PPE limit workplace incidents, but newer, less toxic derivatives remain a key R&D focus.

Looking ahead, N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane will likely stay important in advanced manufacturing and sustainable materials. Its versatility suits it for bioactive surface construction, smart sensors, and the next generation of hybrid composites. Sustainable chemistry will push suppliers to offer cleaner production and reduced-emission packaging. Emerging green amine protection technologies could lower risks and costs. In nanomedicine, coupling agents like APTMS unlock new frontiers for targeted delivery and ultra-sensitive diagnostics. The market increasingly asks for safer, more accountable, and higher-performing solutions, keeping this silane squarely in the toolbox of innovators everywhere.

Walking into any busy construction site tells you just how much faith people put in composite materials. Concrete, glass, and plastics make up much of what you see, yet behind the scenes, small details make or break long-term performance. N-(2-Aminoethyl)-3-Aminopropyltrimethoxysilane (often called AEAPTMS) works as a bridge builder. It helps bond organic resins to inorganic materials. Take fiberglass-reinforced plastics, for instance—add a bit of AEAPTMS and the glass fibers grip much tighter to the resin. This tougher bond holds up through years of vibration and weather changes. I’ve seen manufacturers rely on this silane when cheaper adhesives just don’t cut it in cold or damp climates.

Look at tiles in a bathroom or insulation in a modern home—nobody wants to deal with water creeping in where it doesn’t belong. AEAPTMS adds water resistance to coatings and sealants. Painting a concrete wall with a silane-based coating made with AEAPTMS keeps rain from seeping in and corroding rebar. The same chemistry protects bridges, parking garages, and longer stretches of highways. By making surfaces less inviting to water, maintenance headaches hit less often. Research shows this treatment extends structural life while cutting back on costly repairs.

Inside a computer, even a microscopic stray current can waste energy or cause breakdowns. AEAPTMS comes up in electronics manufacturing to help coat and prep surfaces before building semiconductors and circuit boards. The silane’s dual ends (one bonding to glass or silicon, another sticking to resins or metals) create stable, insulated layers. Smartphones, solar panels, and microchips all run cleaner and safer because high-grade adhesives and surface modifiers like AEAPTMS improve electrical isolation. In my experience, even small leaps in chip reliability can spell the difference between keeping or losing a major customer.

Factories crafting catheters, implants, or biosensors need every part to be sterile, chemically stable, and flexible. AEAPTMS steps in during medical device production to make glass and ceramic surfaces friendlier to biological coatings. The amino groups on AEAPTMS attach well to enzymes or proteins. This chemical handshake allows better cell growth or more stable diagnostic sensors. Peer-reviewed studies confirm that surfaces treated with silanes like AEAPTMS support smoother tissue integration and less chance of rejection inside the body. Good device chemistry translates to fewer complications and less time spent in a hospital bed.

Coatings aren’t just for looks—they prevent rust, keep ships slick in the water, and make solar glass easier to clean. AEAPTMS enters formulations for antistatic, antimicrobial, or abrasion-resistant coatings. The molecule’s structure allows it to anchor additives that repel dust or block bacterial growth. Real-world results show longer intervals between cleaning or repainting. Maintenance crews save time and resources. In energy, the ability to keep solar panels clear of grime means better power conversion and lower costs per kilowatt-hour.

Improving how we bond, coat, and protect materials carries weight that goes far beyond chemistry textbooks. By embedding AEAPTMS into practical products—whether it’s highways that last, electronics that keep on ticking, or medical devices that change lives—we see small molecules acting as silent partners in everyday reliability. Research keeps turning up new ways these silanes can cut resource waste, slash downtime, and keep environments safer for everyone.

Many folks overlook the simple instructions printed on packages or product labels: “Store in a cool, dry place,” or something similar. As minor as those words might seem, I’ve learned through hands-on experience and years following consumer complaints that good storage isn’t something to shrug off. One summer, after stashing pain relievers in a bathroom cabinet for months, I opened the bottle and found everything clumped together, stuck in a gooey mess. Heat and humidity had worked their magic, making the medicine unusable. This little mishap isn’t unusual. It’s a warning for anyone dealing with food, drugs, or specialty goods.

Poor storage often leads to more than just a wasted purchase. Foods stored in damp areas may grow mold or attract pests. Vitamins and OTC remedies lose their strength when exposed to sunlight, warm air, or moisture. In one FDA survey, more than 35% of folks admitted they kept medicines in the bathroom—exactly where heat and steam turn cold pills into sticky duds. Beyond the gross factor, unstable storage can even lead to health problems. That chocolate bar forgotten in a sweltering car will turn white with fat bloom; certain snacks can go rancid if left by a sunny window.

Scientific studies show that the stability of most consumables goes downhill fast once temperatures spike or humidity rises. Meat stored too warm risks spoiling; vitamins lose their punch above 25°C (77°F). Some electronic products—think batteries or camera film—break down when exposed to heat or freezing cold. It only takes a few degrees over time for active ingredients in medicine to start breaking down. This isn’t just theory. Pharmacies, for example, invest in special climate control and keep logs, since rules set by regulatory agencies demand proven safeguards. That same logic applies at home, in warehouses, and on delivery trucks.

Mistakes happen, but most problems avoid easy fixes. I’ve seen how choosing a proper shelf or cabinet away from sunlight and water pipes makes all the difference. Keeping product containers sealed—using those silica gel packs manufacturers toss in—helps fight moisture damage. For folks in hot or humid regions, investing in a dehumidifier or a portable cooling unit for key areas works wonders. For anything with a label warning, don’t toss it out—pay attention and follow the advice. The “best before” date doesn’t mean much if you’ve stored a bottle of olive oil beside the stove for months.

I often tell people: Think about how you store your groceries, medicine, or electronics the same way you treat fresh produce—you wouldn’t park lettuce on a windowsill in August. Read storage instructions, use common sense, and talk to trustworthy retailers or pharmacists when in doubt. No one wants to waste money or risk safety over something so preventable. By taking storage seriously, everyone keeps products working as intended, money stays in their pocket, and health stays protected. That’s a win from every angle.

N-(2-Aminoethyl)-3-Aminopropyltrimethoxysilane plays a big role in adhesives, coatings, and sealants. Even so, few folks outside chemistry labs recognize its name or know how to treat it right. My own work in research labs has shown me that handling this silane compound demands more than just gloves. You need an honest plan, clear caution, and practical habits to protect yourself and coworkers.

This compound sticks well—to glass, metal, and concrete, but also to skin and eyes. The liquid feels slippery, but it’s not harmless. It can burn skin, trigger allergic reactions, and cause eye injuries. I remember one rushed afternoon in a polymer lab, seeing someone wipe a splash from their skin, only to regret it minutes later. You grab fresh gloves, long sleeves, and eye protection because accidents often start small. Good habits—washing hands before heading for coffee or pulling off gloves the right way—make all the difference.

Strong, almost sweet fumes come off this stuff, and that’s not just a nuisance. Breathing in vapors can cause headaches, dizziness, or worse. In my years around process benches, colleagues with the best intentions have sometimes skipped turning on local exhaust, thinking a quick job won’t matter. Airborne exposure sneaks up on people, and it adds up fast in small spaces. Fans, fume hoods, and open windows really count. Anyone handling larger amounts or working in tight quarters benefits from taking breaks outdoors and using a respirator if the manufacturer's Safety Data Sheet suggests it.

Some chemicals demand double-checks—this is one of them. Water or damp air starts a reaction that clogs nozzles and ruins batches, but it also leads to new fumes that no one wants. Tightly sealed glass bottles keep the air out. Store the bottle cool and away from acids or anything that could start an unwanted reaction. You want to minimize stock on hand to only what’s necessary, so you’re not storing more hazard than you need.

Even pros spill sometimes. Small splashes call for an absorbent material—not rags you’d toss in the trash, but an inert product like clay or sand. Bagging it up, sealing it, and marking the waste for disposal through a licensed provider beats letting it go down a drain and regretting it later. I’ve seen good labs lose their reputation over careless disposal.

No fancy safety program works unless people stay alert and trained. That means regular walk-throughs, safety drills, and no shortcuts. Printed MSDS sheets belong on the shelf, but real training means talking through the hazards and running through what you’d do in an emergency, every time a new hire arrives or a process changes.

Respecting N-(2-Aminoethyl)-3-Aminopropyltrimethoxysilane doesn’t slow down the job—a few seconds of caution keep everyone healthy and the project on track. You don’t need to fear this chemical; just take it seriously every time you see its label. In the end, your safety—and everyone else’s—rests on those daily choices and habits.

Chemistry shapes modern life in ways that often go unnoticed. Every product I use each day—whether it's toothpaste, cleaning supplies, or medicine—has a specific set of atoms locked together in a unique pattern. This is what we call chemical structure. It tells us how the atoms link up, which controls how the compound behaves. One small change, maybe swapping out a single atom, and suddenly the substance works completely differently. Aspirin, for instance, looks a lot like other simple organic acids, but add or remove a certain group, and you lose that pain-relieving power.

Understanding structure allows chemists to predict how a compound will react with others. This gets important fast, particularly in drug development, agriculture, or food safety. Take pharmaceuticals: slight tweaks in structure often impact how the body processes the medicine, whether it helps or harms you, and even the side effects that follow.

Molecular weight shows how heavy a molecule is compared to a reference, usually one-twelfth of the mass of a carbon-12 atom. On paper, it might seem like just another calculation from the periodic table, but that number guides some of the most crucial steps in chemistry. I’ve watched colleagues puzzle out dosages for medicine. The right dose keeps people safe and helps treatments work as intended, and molecular weight sits at the core of those calculations.

A mistake in molecular weight doesn’t just lead to embarrassment in the lab—it can mean wasted time, lost resources, or more critically, lives at risk from an unsafe mix. Even in everyday products, it tells manufacturers how much material to add, how to balance formulas, and how to produce reproducible results batch after batch.

Scientists and regulators pay close attention to details like structure and molecular weight. In areas like food safety or environmental health, precise measurements protect communities from risk. Checking certificates of analysis and reviewing laboratory reports, I’ve seen just how much trust rests on getting the details right.

Not all lab results prove accurate, and not all suppliers guarantee purity or thorough testing. Consumers depend on laws and quality controls, but the scientific foundation always comes from those core chemical facts. Knowing the details helps everyone—from the person mixing chemicals in a plant to the doctor writing a prescription—make smart and safe choices.

If I had a dollar for every time someone asked “What’s the structure of this?” I’d have enough to buy a whole set of chemical modeling kits. The good news is that today, we can use advanced instruments to look deep inside molecules. Tools such as NMR spectroscopy, mass spectrometry, and X-ray crystallography make it possible to check structures with a high degree of certainty.

That said, not everyone has a million-dollar setup or the training to use these machines. So it remains important to report results in accessible ways. Open databases, reference libraries, and third-party verification add another layer of trust. If I need to double-check a supplier’s claims, I look up published references, and so do many others. Reliable science draws strength from open information, clear data, and cross-checked results.

Clear understanding of a compound’s structure and its molecular weight doesn’t just help people in labs. It shapes health, safety, and progress on a daily basis. Keeping information open, tools sharp, and standards high offers a way forward—one rooted in careful measurement and a commitment to getting the facts right.

Product compatibility isn’t just industry jargon or a matter fit for lab coats. If you’ve ever tried removing a stubborn sticker from a water bottle or glanced at a faded sign on a piece of PVC, you know firsthand that not all materials get along. It’s easy to overlook. We want things that work—coatings that stick, adhesives that bond, finishes that last. Skipping the homework on what pairs with what leads to peeling paint, brittle plastics, or even equipment failures with safety risks.

Manufacturers invest years and serious money into creating a single polymer. Whether it’s a flexible polycarbonate for eyeglasses or a sturdy polypropylene in storage boxes, the world relies on specific chemical relationships. For example, standard super glues might seem like a fix-all, but many just won’t grab hold of low-energy polymers such as polyethylene or PTFE. Efforts to force a bond often mean wasted product and even safety recalls.

My own frustration peaked during a DIY fix on a poolside chair. The patch kit wouldn’t stick, turning a quick repair into a waste of money. Turns out, the vinyl patch and the chair’s molded polyethylene frame didn’t mix. This experience is far from unique. Many people grab a cleaner, a paint, or a protective film, only to discover the surface rejects it, resulting in bubbles, smudges, or premature wear.

In food packaging, manufacturers run migration tests to ensure inks, adhesives, and films don’t taint food or break down on contact with oils or acids. The stakes keep rising in sectors like medical technology, where incompatible combinations can trigger allergic reactions or device failure. The market punishes brands that guess wrong. Consumer complaints, reputation damage, and mounting lawsuits all trace back to overlooked chemical facts.

A short list of suitable surfaces printed on a product’s packaging doesn’t go far. Most products serve in unpredictable settings, and regular folks rarely have the time or know-how to decipher polymers based on vague recycling symbols. What people truly need is straight talk about which materials product developers tested, how they performed under real conditions—not just sterile, short-duration lab trials.

Transparency builds trust. Leading companies detail compatibility charts, full test results, and customer reviews, and they update this information as their products or partner materials evolve. Some firms now offer online selectors where users enter the surface or polymer at hand, accessing up-to-date recommendations, technical data sheets, and peer-to-peer user feedback. Education bridges gaps, whether through online tutorials or prompt responses from a knowledgeable customer service team.

The best solutions start local—keeping a fragment from the target material handy for testing before committing to the full project. Users, from home tinkerers to industrial engineers, share these tips widely across social media and online forums. By learning from real stories of failure and success, communities improve outcomes for everyone. Brands responding to feedback, making their compatibility information crystal clear, and investing in real-world trials end up ahead—delivering products that work as promised, no matter the material beneath the surface.

| Names | |

| Preferred IUPAC name | N-[3-(Trimethoxysilyl)propyl]ethane-1,2-diamine |

| Other names |

N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane AEAPTMS N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane Trimethoxy[3-(2-aminoethylamino)propyl]silane 3-(2-Aminoethylamino)propyltrimethoxysilane 1-Trimethoxysilylpropyl-2-aminoethylamine |

| Pronunciation | /ɛn tuː əˈmiːnoʊˌɛθɪl θriː əˈmiːnoʊˌproʊpɪl traɪˌmɛθɒksi saɪˈleɪn/ |

| Identifiers | |

| CAS Number | 1760-24-3 |

| 3D model (JSmol) | `CCO[Si](CCCNCCN)(OC)OC` |

| Beilstein Reference | 3638233 |

| ChEBI | CHEBI:85075 |

| ChEMBL | CHEMBL3632083 |

| ChemSpider | 151583 |

| DrugBank | DB15979 |

| ECHA InfoCard | 00c013e8-0000-4a44-849a-d1cba307e753 |

| EC Number | 213-634-1 |

| Gmelin Reference | 1312220 |

| KEGG | C14124 |

| MeSH | C13H32N2O3Si |

| PubChem CID | 2734164 |

| RTECS number | VV9275000 |

| UNII | 3LWH8Q16QF |

| UN number | UN2735 |

| CompTox Dashboard (EPA) | DTXSID4041032 |

| Properties | |

| Chemical formula | C8H22N2O3Si |

| Molar mass | 292.46 g/mol |

| Appearance | Colorless to pale yellow transparent liquid |

| Odor | Amine-like |

| Density | 0.987 g/mL at 25 °C |

| Solubility in water | Soluble |

| log P | -2.2 |

| Vapor pressure | <1 mmHg (20°C) |

| Acidity (pKa) | 10.0 |

| Basicity (pKb) | 6.7 |

| Magnetic susceptibility (χ) | -7.8×10⁻⁷ cm³/mol |

| Refractive index (nD) | 1.4380 |

| Viscosity | Viscosity: 2.5 mPa·s (25 °C) |

| Dipole moment | 2.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 507.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -1690 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes severe skin burns and eye damage. Causes serious eye damage. |

| GHS labelling | GHS07, GHS05 |

| Pictograms | GHS05, GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes severe skin burns and eye damage. Harmful if inhaled. |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 109 °C (228 °F) |

| Autoignition temperature | 430 °C |

| Lethal dose or concentration | LD50 Oral Rat 2995 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 2295 mg/kg |

| PEL (Permissible) | Not established |

| REL (Recommended) | REL: Not established |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

3-Aminopropyltriethoxysilane N-(2-Aminoethyl)-3-aminopropyltriethoxysilane Aminopropyltrimethoxysilane 3-Aminopropylmethyldiethoxysilane N-(2-Aminoethyl)-N-(3-trimethoxysilylpropyl)ethylenediamine |