Back in the push for higher performance in plastics and composite materials, chemists started exploring silanes with functional groups that could help bridge the gap between organic and inorganic surfaces. Vinyltri(Isopropoxy)Silane came from this context, picking up momentum in the 1980s as a compelling coupling agent. Its origin links to efforts in boosting adhesion between glass fibers and polymer matrices in reinforced resins. By introducing a vinyl group, the molecule could form chemical bonds with organic polymers during curing, lending strength and durability to finished materials. Early documentation showed up in patent literature, long before the chemical made its way into major plastics factories.

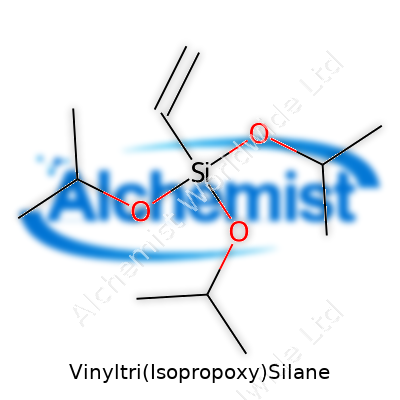

Vinyltri(Isopropoxy)Silane serves in industries like construction, automotive, electronics, and adhesives. The vinyl group at one end of the molecule allows it to react with polymer matrices, such as those used in cross-linked polyethylene (PEX) pipes. Its isopropoxy groups help form bonds with inorganic surfaces like silica, glass, ceramics, and certain metals. These dual functions make the compound a go-to solution for improving adhesion, water-resistance, and overall performance in applications that span harsh environments and regular daily wear.

This silane appears as a colorless to pale yellow transparent liquid, carrying a distinct odor reminiscent of alcohols. It weighs in at around 246 grams per mole. The boiling point rises close to 180–190°C under standard pressure. Its flash point hovers near 65°C, which means the handling process in plant environments demands care around open flames or sparks. Vinyltri(Isopropoxy)Silane dissolves well in common organic solvents including alcohols, esters, ketones, and ethers, but struggles in water due to rapid hydrolysis. This reactivity with moisture proves useful in coatings, sealants, and resin systems.

Each batch of Vinyltri(Isopropoxy)Silane requires clear product labeling with the CAS number 15332-99-7, molecular formula C11H24O3Si, and purity (typically above 97%). Manufacturers often indicate moisture content, color (APHA value), and refractive index to guarantee performance in nuanced industrial processes. Shipments need proper hazardous material labels, including UN number (if required) for international transport. Labels also spell out storage recommendations—dry, cool, well-ventilated spaces to slow down unwanted hydrolysis—along with batch and manufacturing dates for traceability.

The core reaction for producing Vinyltri(Isopropoxy)Silane relies on chlorosilanes and isopropanol. Manufacturers run these processes under controlled temperatures, using acid scavengers and inert gas to push out any residual hydrochloric acid. The step-by-step routine includes feeding vinyltrichlorosilane into a reaction vessel packed with isopropanol, followed by careful distillation to separate out the finished alkoxysilane. Purification by fractional distillation ensures high concentration; any water must stay out of the process, since even minor contamination triggers hydrolysis and could reduce yield considerably.

The vinyl group in this compound plugs directly into free radical polymerizations, making it a valuable co-monomer in crosslinking. On inorganic surfaces, its isopropoxy groups split off under acidic or basic conditions, revealing reactive silanol groups that latch onto surfaces like glass or ceramics. Technical teams have explored further modifications—like hydrolysis in the presence of catalysts, or managing side reactions with amines or other silanes to adjust surface activity. These tweaks let end-users dial in the right level of hydrophobicity, chemical resistance, or bond strength for complex environments. Over the years, companies have also tested blending it with other silanes to target tougher substrates or stricter environmental codes.

Chemists often encounter Vinyltri(Isopropoxy)Silane under names like VTIPS, Tri(isopropoxy)vinylsilane, or Vinyltris(2-propoxy)silane. International catalogs might list it as Silane, triisopropoxyvinyl- or simply "vinylsilane isopropoxy derivative". Several chemical suppliers have coined proprietary names for their versions, but each ties back to the same core formula and functional groups.

Safe handling begins with eye protection, chemical-resistant gloves, and working inside a vented enclosure or fume hood. The isopropoxy groups can release flammable alcohol vapors, so plant operators keep potential ignition sources away during transfer and use. The substance irritates eyes, skin, and respiratory passages, so spill response and eyewash stations must stay within line of sight in workshops. Tanks and containers should remain airtight, since prolonged moisture exposure can cause dangerous build-ups of pressure through hydrolysis. Industry-standard safety data sheets (SDSs) provide site-specific recommendations and emergency guidance for personnel.

Manufacturers and researchers both value this chemical for coating glass fibers in composites, treating mineral fillers, and preparing weather-resistant sealants. Its value shows up in PEX pipes, automotive gaskets, architectural sealants, and electronic potting compounds. The vinyl group builds strong, heat-stable links during polymerization, while the silane tail grabs onto inorganic fillers and surfaces. The result: finished products that last longer outdoors, resist cracking under stress, and maintain integrity across temperature swings.

Research over decades has mapped out new uses for Vinyltri(Isopropoxy)Silane. Teams have investigated its ability to boost flame resistance in plastics and enable greener water-based coatings through silane technology. Polymer scientists probe how it alters dispersion of pigments and mineral fillers, aiming for tougher, lighter, or more flexible materials. Some universities dive deep into hybrid material systems, combining this silane with other organofunctional silanes to extend its benefits into areas like printable electronics or nano-composites. Each new avenue calls for more rigorous structure-property studies, and companies often cross-share with academic labs to validate and improve formulations.

Toxicologists focus on inhalation and skin contact as main exposure pathways on production lines and in downstream manufacturing. Short-term contact can lead to irritation or burns, while chronic exposure carries a risk of sensitization for some workers. Animal studies point to moderate toxicity at high doses, mostly tied to the release of isopropanol and reactive fragments during hydrolysis. Proper ventilation, training, and upkeep of material safety data keep real-world incident rates low, yet there’s always a push for cleaner process chemistry and stricter personal protective equipment use. Ongoing research follows how breakdown products react in the body and environment, aiming to map out any long-term impact well before these materials see broader use.

Trends in advanced materials lean more and more on chemistry that connects organic and inorganic worlds. We keep seeing Vinyltri(Isopropoxy)Silane as a contender—not just for today’s composites, but for biodegradable plastics, medical adhesives, and even green concrete technologies. Ongoing work looks at how to cut down residual emissions during application, swap out solvents for water-based systems, and push for renewable feedstocks in silane production. There’s still much to learn in areas such as improving recyclability and reducing trace environmental impact. Chemical companies and labs that take the lead in solving these puzzles will have the edge as building standards, consumer safety, and climate targets raise the bar for performance and responsibility.

Vinyltri(isopropoxy)silane might sound like something cooked up in a distant corner of a science lab, but it’s become a workhorse for people dealing with plastics, adhesives, coatings, and advanced materials. Its main job is to help things stick together better. Take the example of plastics manufacturers. They’re always searching for ways to make materials tougher and longer-lasting. When mixing different substances, they need a “bridge” that helps the ingredients bond at a molecular level. That’s where this chemical steps in. It doesn’t just float around in the mix; it forms strong chemical links between organic materials, like plastics or rubbers, and inorganic stuff, such as glass or minerals. This knack for building a chemical bridge means you see less cracking, fewer faults, and better performance in the end product.

Look at fiberglass. Many people know it for its strength and lightweight feel. The trick to making fiberglass so dependable lies in coupling agents—chemicals that link the glass fibers to the plastic resin. Vinyltri(isopropoxy)silane plays a part here. It grabs onto the glass and the plastic resin at the same time, so the result resists water, stands up to wear, and lasts through wild temperature swings.

Anyone who’s ever scraped peeling paint knows how frustrating poor adhesion can get. Paint manufacturers rely on silane compounds like this one to promote sticking power. With just a small amount blended in, paint grabs onto the wall, car frame, or industrial machinery. That means less peeling and chipping, especially in locations exposed to lots of weather or sunlight. It also reduces costs in the long run. Less maintenance and fewer touch-ups help businesses save both money and time.

Vinyltri(isopropoxy)silane shows up in electrical applications, specifically with wire and cable insulation. Water seeping into cables can cause huge problems, from power outages to short circuits. Adding this silane to the insulation process helps keep out moisture. Picture big underground cables or the wiring in electric cars. Without a good barrier, water creeps in and accelerates damage. Silane helps seal out leaks and makes cables last longer. The tech is subtle but makes a difference you notice every time the lights come on without fail.

Chemicals with isopropoxy groups, like this one, need careful handling. Breathing in vapors or getting them on your skin can cause irritation. Manufacturers address these risks with airtight handling systems and protective gear. Regulatory agencies monitor how much is released into the environment and how workers are protected.

There’s also a growing push for green chemistry. Companies are exploring ways to design silanes that deliver the same performance, but with fewer environmental downsides. Some approaches use lower-toxicity starting materials or improve the way the chemical is integrated into end products, so less of it escapes into the air or water.

Silane chemistry supports global industries worth billions, from construction to electronics. Its value comes from reducing waste and improving material quality. Research continues to improve its performance and safety, which pushes both innovation and market growth. Keeping an eye on production, safety, and smarter alternatives helps balance industrial progress with public health concerns.

Vinyltri(isopropoxy)silane isn’t the sort of stuff you find under the kitchen sink, and anyone who’s opened a drum of it in a lab or on a worksite knows care matters. With chemicals like this, it’s not only about reading labels or material safety sheets; it’s about respecting the way a spill or splash can disrupt your day or long-term health. Breathing in those vapors, letting drops linger on your skin, or mishandling open containers brings more trouble than many realize.

Every time I’ve handled silanes, one rule has stuck: full personal protective equipment goes on before the container opens. This starts with safety goggles. Regular glasses just don’t cut it; splashes can sneak past the sides. Chemical-resistant gloves, preferably nitrile, are a must. I’ve seen sleeves soaked through from a careless pour, and skin rashes aren’t worth skipping gloves. Long sleeves and a lab coat or chemical apron stop those surprise drips from reaching vulnerable skin.

Good ventilation isn’t negotiable. Vinyltri(isopropoxy)silane vapor feels harsh in the throat and nose. A fume hood or proper exhaust fan makes the job less risky. On sunny days, I’ve worked outside for extra airflow. No one in the room should ignore the distinct odor— it’s an early warning sign things aren’t right.

There’s always someone who thinks “just this once” doesn’t matter, but flammable vapors change minds fast. Vinyltri(isopropoxy)silane catches fire quickly if stored by heat sources or open flames. I keep it stored in a cool, dry spot away from oxidizers, acids, and spark risks. The container stays tightly closed with the original label front and center, since transferred chemicals end up causing confusion or worse.

Spills get immediate attention. Sand or a proper absorbent traps the liquid, and then the used absorbent goes in a dedicated, labeled hazardous waste bin. Dumping leftover solution down the drain isn’t just careless—it’s illegal and toxic for waterways. Even small amounts can create slippery floors or spark bigger cleanup headaches.

I’ve worked with newcomers who freeze up during an emergency. Regular training—actual hands-on drills, not just checklists—makes staff confident if something goes wrong. Employers need to walk through spill procedures, discuss the health effects of exposure, and run fire extinguisher demos right where the chemical is kept.

If anyone feels sick—burning eyes, dizziness, or breathlessness, even hours later—they shouldn’t shrug it off. I always urge folks to get checked out and report even minor symptoms. Long-term health counts for more than saving a few minutes.

Many headaches disappear with preparation. Use small quantities when possible, keep clean-up supplies ready, and make sure emergency showers and eyewash stations aren’t blocked. Reviewing safety data sheets before each new task keeps everyone refreshed on the hazards.

Safe handling of vinyltri(isopropoxy)silane comes from respect and careful routines—not luck. Getting lax can cost real harm, not just for the handler but also for co-workers. Every step—goggles, gloves, clean storage, training—spells out a workplace where safety stays front and center every day.

Storing chemicals like vinyltri(isopropoxy)silane can be simple, but it pays to know what works. From my own time in a materials lab, the rules looked strict for a reason. With a compound like this, exposure to air and moisture transforms storage from a box-ticking exercise into a real challenge. One crack in the bottle cap, and you might as well dump half your money down the drain. A careful, dry, tightly sealed container—typically amber glass or corrosion-resistant steel—prevents this from happening. People might stash it away on a regular shelf, but that approach brings risk when temperature or humidity fluctuate.

Manufacturers often print shelf life between six months and a year, but as a chemist at heart, those numbers look like guidelines more than guarantees. If you let moisture or air in, the silane will start to hydrolyze, and you’ll see changes in color or smell. I've seen plenty of chemists try to push a batch beyond its label; results tend to be unreliable, scrap rates climb, and you lose trust in your own supply. Once the silane reacts, you can't recover lost purity. In practical settings, fresh is always best if you want your formulation to work as designed.

A cool, dry storage area makes the difference between a product that lasts and one that turns before its time. Some labs have walk-in refrigerators—nice if you can afford them. More realistically, keeping bottles away from heat sources, windows, or water pipes protects your investment. I always preferred working where temperature sat consistently below 30°C, humidity hovered under 50%, and containers stayed tightly sealed. It's common sense: water triggers hydrolysis, oxygen speeds up aging, and sunlight ruins things faster than many expect. Avoid stacking bottles next to strong acids or oxidizers. Accidents happen, but prevention costs less than cleanup.

Lax handling shows up fast. Caps left loose invite moisture, so your silane degrades before you even open the next batch. Transferring to a smaller, clean container reduces air space and keeps the product fresher. Many skip this, but the payoff in shelf life can be dramatic. Date your containers on arrival and after every opening. It's easy to lose track. I’ve seen torn labels lead to confusion, which snowballs into failed reactions.

Training goes a long way. New lab staff sometimes treat silanes just like common solvents, but repetition and hands-on demonstrations drill in better habits. Regular inventory checks expose any leaks or color changes early. For larger-scale users, installing humidity monitors sounds like overkill, though the cost of a ruined batch justifies it quickly. Keeping samples for routine analysis lets you spot changes before they impact manufacturing.

Cutting corners on storage eats away company profits, results, and credibility. For high-value projects—think coatings or electronics—even minor contamination plays havoc downstream. Paying close attention to shelf life and handling saves time, effort, and money by reducing rework and scrap. I’ve learned firsthand that the small steps up front head off the big headaches down the line.

Chemists and formulators often stop to reconsider the compatibility of additives like Vinyltri(isopropoxy)silane when mixing up adhesives, coatings, and plastics. This organosilane shows up on a long list of primers and coupling agents, so its relationships with other chemicals matter. Ignore that, and you run into problems with poor adhesion, haziness, or even failed product batches.

Vinyltri(isopropoxy)silane presents two distinct personalities. The vinyl group, which brings double bonds, loves to react with unsaturated resins—think polyester, EVA, and some epoxies. Then you have those isopropoxy groups that hydrolyze fast in the presence of water, morphing into silanol and helping the silane cling to inorganic surfaces like glass, fiber, or mineral fillers.

One practical takeaway: in water-based systems, this silane won’t wait around. The isopropoxy groups break down rapidly, and you get a network of silanol that hooks onto any silicious material within reach. This creates solid adhesion when working with glass or mineral-filled composites. If you mix the silane into a resin without care, and the process includes a lot of water, the chemistry can race off ahead of your processing window.

Styrenics, unsaturated polyester resins, vinyl ester, and some rubbers stand out as natural allies. The vinyl functional group on Vinyltri(isopropoxy)silane engages directly with these resin systems, forming strong covalent bonds during the curing step. That bond increases not only mechanical strength, but also moisture resistance and weatherability. Back in my own composite shop days, a touch of vinylsilane helped the resin grab harder to glass mat, cutting down on complaints about delamination after years of service life.

With epoxies, compatibility looks different. The vinyl group won’t react directly with the backbone, though the silanol formed after hydrolysis may still bond to fillers or substrate surfaces. Still, if an epoxy already contains a heavy amine or alcohol content, side reactions might create unpredictable networks or discoloration. Compatibility testing in small lab batches stops headaches later.

Trouble starts bubbling up where highly acidic or basic additives jump into the mix. Silanes are touchy when pH strays too far from the middle. At the wrong pH, hydrolysis and condensation speed up or stall, and the expected chemical bridging might not happen at all. Old-school trial and error, along with a pH meter, saves money better than any catchy sales pitch.

Solvents also shape outcomes. Highly polar solvents—like alcohols—play well, letting the silane spread evenly, while some aggressive ketones or esters can strip or react with processing agents. Chemical companies often point out that too much moisture, or aggressive mixing speeds, trigger unwanted emulsification. Clear, streak-free coatings prove elusive once that happens.

Successful formulations benefit from careful sequencing: add Vinyltri(isopropoxy)silane at the right stage, avoid excess water at the mixing step, and keep the pH steady. Running a simple drawdown on treated and untreated surfaces still tells the truth, even in high-end labs. For bigger batches, in-line monitoring of viscosity and gel time gives early warning before compatibility turns into downtime. That’s a lesson I’ve picked up firsthand: smart up-front testing beats scrambling to fix a defective batch.

In short, Vinyltri(isopropoxy)silane plugs in well with a crowd of organic resins, but its friends list gets shorter in the company of acids, bases, and careless handling. Understanding real compatibility relies on a mix of chemistry basics and tough lessons from the production line, not just technical data sheets.

People often see specialty chemicals as just a technical tool, but daily experience—mixing paint, mending surfaces, or prepping industrial material—shows that the way an additive gets used makes or breaks the final performance. Vinyltri(Isopropoxy)Silane works as a bridge between organic and inorganic materials, helping coatings stick longer or composite parts handle the daily grind. Problems show up fast when you overdo it or guess the measurement.

Manufacturers generally recommend adding Vinyltri(Isopropoxy)Silane at a level between 0.5% and 2% by weight of the base material. This range isn’t a casual suggestion—it comes out of real-world testing. Too little and you won’t see improvement. Too much and you might trigger unwanted side reactions, poor curing, or sticky residues that mess with both looks and strength. I learned in a shop that if the application team drifted above 2%, we’d notice hazy layers or even bubbling. Quality checks flagged those batches every time.

This chemical works best when mixed thoroughly into the resin or polymer base before fillers or pigments get tossed in. Direct addition lets it bond with both sides of your material: the organic resin grabs the vinyl group, and the isopropoxy part latches onto the surface of glass, metal, or mineral particles. If you only coat the filler, much of the agent ends up wasted, and surfaces stay untreated.

Start by measuring out the right proportion for your batch. If you’re working with 100 kilograms of unsaturated polyester resin for fiberglass parts, for instance, use between 500 grams and 2 kilograms of Vinyltri(Isopropoxy)Silane. Mix it directly into the liquid resin, stirring well—slow and steady wins here. If you splash it in too fast or skip blending, uneven distribution almost always follows. Some spots over-cure while others stay tacky or brittle.

Health concerns add another layer to application. This silane releases isopropanol on contact with water or humid air. During lab work, I always kept ventilation strong and skin covered. Breathing in vapor or getting it on hands can irritate, so gloves and goggles just become part of the gear. Any spattered silane gets wiped right away, before it begins to hydrolyze, leaving crusty residues that are tough to clean.

Spills bring another risk—these organosilanes love to bond to surfaces, and if they dry in place, scrubbing might not fix it. Fast response and the right PPE keep workspaces (and people) safer. My colleagues and I put up clear guidelines in our small shop: mix outdoors if possible, store only what you’ll use that day, and set up spills protocols everybody knows by heart.

Anyone seeing strange white spots or poor adhesion after using Vinyltri(Isopropoxy)Silane usually traces it back to one of two things: rushed mixing, or improper handling of the chemical. One fix—after a few bad batches—was switching to low-speed mechanical mixers and training staff to add the silane slower. In almost every industry survey, a methodical, measured approach cuts down on rejects and improves reliability.

Users often find that matching the manufacturer’s recommended dosage and mixing method keeps headaches to a minimum. Too many times, trying to “improve” the process by adding more silane or skipping steps backfires. Practical experience, not only in labs but in real shops, keeps pointing to the same lesson—follow the recipe, check the batch early on, and keep your workplace safe.

| Names | |

| Preferred IUPAC name | Tri(propan-2-yloxy)ethenylsilane |

| Other names |

TRIS(1-METHYLPROPOXY)VINYLSILANE Triisopropoxyvinylsilane Vinyltriisopropoxysilane 2-Propenyltri(1-methylethoxy)silane Vinyltris(1-methylethoxy)silane |

| Pronunciation | /ˌvaɪ.nəlˌtraɪ.aɪˈsɒprəˌkɒksiˈsaɪ.leɪn/ |

| Identifiers | |

| CAS Number | 17980-32-4 |

| 3D model (JSmol) | `"JSmol" model string for Vinyltri(isopropoxy)silane: C[Si](OC(C)C)(OC(C)C)OC(C)C` |

| Beilstein Reference | 3970478 |

| ChEBI | CHEBI:87154 |

| ChEMBL | CHEMBL3280595 |

| ChemSpider | 164469 |

| DrugBank | null |

| ECHA InfoCard | 03-2119959276-36-0000 |

| EC Number | 412-270-5 |

| Gmelin Reference | 2031579 |

| KEGG | C18630 |

| MeSH | D014032 |

| PubChem CID | 6910805 |

| RTECS number | YV9620000 |

| UNII | 9QZ2F1W02F |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | DTXSID1020642 |

| Properties | |

| Chemical formula | C11H26O3Si |

| Molar mass | 292.47 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Alcohol-like |

| Density | 0.88 g/mL at 25 °C(lit.) |

| Solubility in water | insoluble |

| log P | 2.3 |

| Vapor pressure | 0.5 hPa (20 °C) |

| Acidity (pKa) | Acidity (pKa): ~25 |

| Basicity (pKb) | 12.16 |

| Magnetic susceptibility (χ) | -7.0E-6 cm³/mol |

| Refractive index (nD) | 1.4100 |

| Viscosity | 3 mPa·s |

| Dipole moment | 1.05 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 642.8 J·mol⁻¹·K⁻¹ |

| Pharmacology | |

| ATC code | '' |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H319, H332 |

| Precautionary statements | Precautionary statements: P261, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-2-0-" |

| Flash point | 76 °C |

| Autoignition temperature | 335°C |

| Lethal dose or concentration | LD50 Oral Rat 11,928 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat = 7,130 mg/kg |

| NIOSH | VVQ38000 |

| PEL (Permissible) | PEL: Not established |

| Related compounds | |

| Related compounds |

Vinyltrimethoxysilane Vinyltriethoxysilane Vinyltris(2-methoxyethoxy)silane Vinyltriacetoxysilane Vinyltrichlorosilane |